Since there are so many folks in here that are compressor wizards, (yes TW, I moved my aftercooler to after the tank (Thanks btw)), what kind of trouble am I looking at if I take two 17cfm compressors, put check valves after the tanks so they only worry about their own pressure, and tee them to the main shop air line? I mean, I know I won’t get 34CFM or anything amazing but, I figure that way, I don’t have one compressor always being “boss” Ideas?

I like this idea.

I may consider not adding more check valves and make a manifold between both tanks together. I would rather worried about only system psi instead of; system, tank 1 and tank 2 pressure.

If you do do this now the pipework after the new check valves have become a new “Tank” of air without a pressure blow off safety.

Theoretically Why not? The pipework static pressure and the combined compressor output will likely be the only thing limiting this.

You have to solve the main problems

Short cycling the compressors because they and turning on and off too quickly. this is where need some spread between set points comes into play . Setting 10-15psi between compressors turn on point or a timed delay.

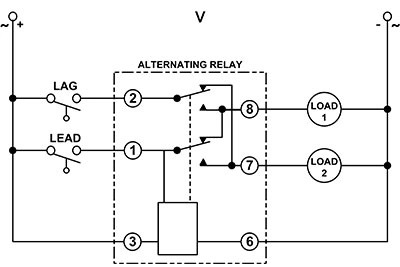

Alternating the which compressor will be the the first to turn NO also needs to be addressed so one compressor does not see all the run time. . Here you need to add an alternating relay that can deal with two loads that has space for a “lead” compressor “lag” compressor then timed or psi switched to both ON. this will keep the run times even.

Edit:

This is close to the logic we are looking for

" DPDT CROSS-WIRED

In the off state (Figure D), both the LEAD Switch and the LAG Switch are open, the Alternating Relay is in the LOAD 1 position, and both LOAD 1 & LOAD 2 are off. The red LED marked “LOAD 1” is ON. When the LEAD Switch closes, it energizes LOAD 1. As long as the LEAD Switch remains closed, LOAD 1 remains energized. If the LAG Switch closes, it energizes LOAD 2. When the LAG Switch opens, LOAD 2 is turned off. When the LEAD Switch opens, LOAD 1 is turned off and the Alternating Relay toggles to the LOAD 2 position. The red LED marked “LOAD 2” is ON. When the LEAD Switch closes, it turns on LOAD 2. If the LAG Switch closes, it will energize LOAD 1. When the LAG Switch opens, LOAD 1 is turned off. When the LEAD Switch opens, LOAD 2 is turned off, the Alternating Relay toggles back to the LOAD 1 position, the red LED marked “LOAD 1” is ON, and the process can be repeated. NOTE: the LEAD switch must always close before the LAG switch and must always open after the LAG switch."

Lead is switched ON by tank pressure and Lag is ON by time or a 2nd pressure switch

“I may consider not adding more check valves and make a manifold between both tanks together. I would rather worried about only system psi instead of; system, tank 1 and tank 2 pressure.”

Using a manifold would involve doing the complex "“alternating method” with control, relays etc to avoid the issue of COMP1 always being first and maybe COMP2 never really runs, or goes short. I have a “dry tank” downstream with a popoff but, I think, putting one in each leg would still be a good idea. I have seen plans for using a logic controller, (arduinos etc) to make one master etc, but I’m looking for a simple mechanical solution if at all possible. Maybe I just up the insyrance premium and give it a try.

Could you use one heavy duty set of points to start both compressors at the same time? That is if you don’t want to do the alternating cycles.

I keep thinking that this makes sense but then when the compressor needs to run longer to pressurize the extra capacity, I wonder if that extra wear/tear is something to be concerned.

I do agree that the relay system makes your head swim a bit. It makes great sense but so many more pieces.

Relay is the way to go. It runs #1, then the next cycle runs #2. Alternating relays are readily available. I would plumb the tanks together—twice the reserve. You still won’t get double the cfm unless they both run together. Output is only relative to what the design of the compressor unit.