I’m about to cut 1/4” hot rolled with my razorcut45. I take good notes but seem to be missing my note from the last time I cut 1/4”. What settings is everyone using? So far I’ve programmed 25ipm, 40amps, pierce higher of .15, cut height of .125

I have a RW45 and cut 1/4" at 48 IPM at 45 A .15 P .060 CH.

I do have a Hypertherm torch but that will get you very close

1 Like

That’s what I had programmed based on my experience, good to know I’m on the right track, I’ll do a couple of test cuts tomorrow

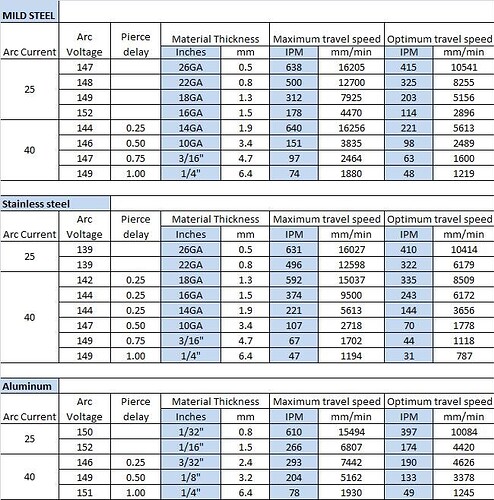

This has been useful for ballpark, although conservative, cut settings.