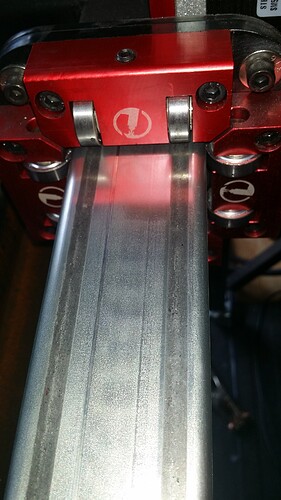

I have aligned the table many, many times and I still get a deep groove on top of the y tube. The deep groove is caused by a seam weld from the gantry. The gantry get stuck and then the lead screw spins freely. I realigned the gantry, the bearings and the table itself. I am open to suggestions

…Make sure you don’t have a failed bearing. By groove are you talking of the visible line just to the right of the left side bearing track?

yes, that is groove I am talking about. Took the gantry off the rail and notice its the weld seam rubbing against the y tube. All the bearings appear to be good.

Hi, this was actually a manufacturing issue, the weld seam of the tube is supposed to be on the bottom wall. What happens is that when you loosen the bolts to level the gantry, the gantry is able to drop slightly due to the bolt clearances which allows the weld to contact the top surface of the rail tube.

We can certainly send you out a new carriage weldment, but its actually fairly easy to fix. Before breaking the bolts loosen to align the gantry, simply place a small piece of card stock on top of the Y axis rail tube. When you loosen the bolts the weld will drop down onto the card stock. After leveling the card stock can be removed and there will be clearance between the weld and the rail.

I leveled the gantry again like you said Daniel and man it is tight under there. As of right now I can barely slide a strip of paper between the tube and carriage. I ran the crossfire breakin program without a problem. I will fill up the water table and cut tomorrow. I will keep everyone posted! Thank you @langmuir-daniel

Thanks for asking the question. I just ran into this problem today. Im going to see if i can fix the issue.