I think you mean 75 psi. You can just add a regulator to the rear and adjust the pressure as needed.

3/16" (7ga) @ 40ipm and 37Amps. Very little dross. Pierce Delay (P2) in G-code… Is that 2 seconds? Razorweld 45 - .06 Shim. 1mm Shielded tip from [mechanic416] on ebay.

Thanks guys, the pleasure is all mine.

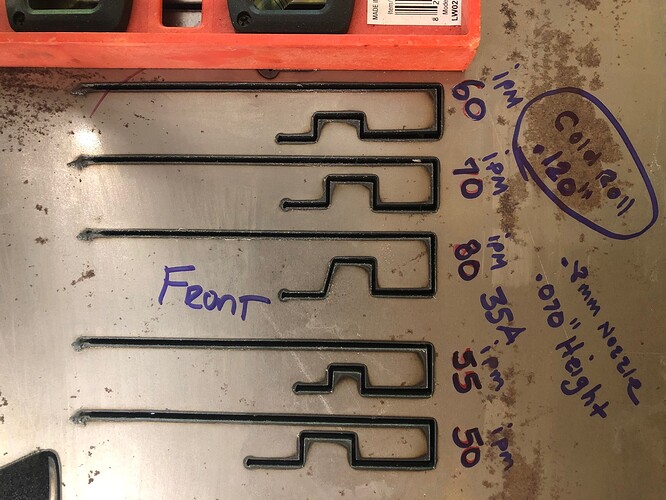

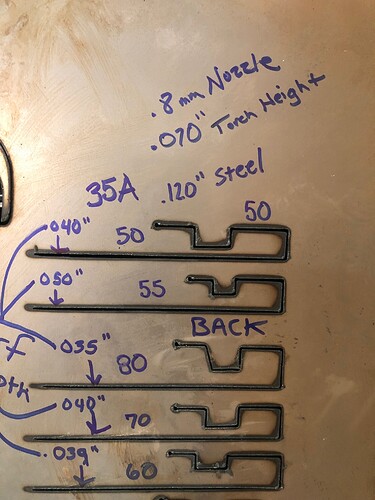

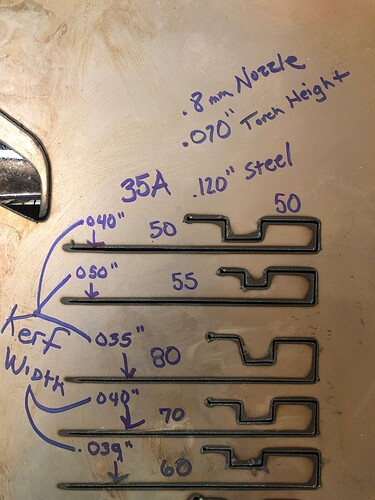

70 ipm was the winner although all were pretty good!

70 ipm was good speed with no dross to speak of & a kerf width of .040”

.120” cold rolled steel

.070 TH

.8mm nozzle

35 A

1.0 sec PD

70 psi on RW45cut Gauge

Dry dry dry air!

A 0.8mm tip/nozzle is only rated at 30 amps max. They are not going to last long at 35 amps

Looks good. Steel plates for shooting?

Yes. For a buddy of mine. I made one before free hand… this is oh so much better.

I know this, it’s just a sacrifice for the smaller kerf width😉

Thank you for the chart and info.

hello everyone. I am a total NEWB at CAD and CNC. I just recieved my table with the new razorweld45

and I cannot find the tip size. only mark I found was 45amp. any help?

I believe they are 1.0mm. At least for my torch - but that was a year & a bit ago (I was batch 2 of the original orders). I also got 0.6mm, 0.8mm and I thought I saw a 0.9mm available.

You need to match the power to the tip size - you’ll blow out a 0.6mm tip if you use 45A. I typically used max power (45A) so the 1mm tip. But if you’re going to do fine details on thin material you might want the 0.6mm at 25A.

thanks for that. I have an old thermodynamics plasma cutter and it shows the tip size on them but not the new razorcut. I guess I will have to run out and buy some and see if the new ones are marked.

Which torch do you have with the Razorcut?

The new X45 torch is a 1.0mm tip and from my understanding that is the only size that fits the torch which appears to be a limitation of the new torch.

I have the new x45 torch and after some research yes it is the only tip I can use for it.

Anyone have a current chart ? or 16 gauge settings for Razorweld 45 CNC and what tip works the best ? Having a lot of issues with kerf width and large holes at the ends of my cuts . I am sure it is a setting issue just trying to get it straight…

This might help:

https://docs.google.com/spreadsheets/u/0/d/12SPhiHimP9lWIOJTGaHhDAiaQoUz5Hq0YjbL92mMBSo/htmlview#

Thank You ! been testing trying to get cuts without defects . It is challenging the Fusion 360 having more information than you need makes it difficult . The biggest problem i am having is “divits” where the torch comes in and maybe stops was trying to run with no lead out. Not sure thats the answer either … The lead ins and pierce height seem to be critical . I need to control where it goes in so the the divits are located in inconspicuous places. any and all help appreciated

anyway thank you