Not sure if this is the right category for this so pardon me if it’s not. I have had my XR up and running for about 2 weeks now & have noticed a few repeated issues that have been intermittent.

Here is my setup/equipment,

-Langmuir XR

-Hypertherm 65 Sync W/ CPC Port & cable

-Quincy 60 gal compressor

-2 Seperate Desiccant Filters

-Fusion 360

-Sheetcam

The first issue is the torch moving before voltage has been sensed. This error has came up when doing detailed interior cuts & lettering.

The first time I received this error I adjusted the pierce delay in sheetcam from 0.5 to 1.0 seconds, reloaded the program & it finished the entire project without an issue.

The 2nd time I received this error I was using a program with 0.5 pierce delay, I closed the error message and restarted the cut without making any changes & it completed the program without any further issues.

The 3rd time I received this error I was using a program with 1.0 sec pierce delay, shortly into running this program I received the error, I closed the error message & restarted the cut without changing anything & it completed the entire program without any issues.

The 2nd issue I’ve been having is the torch not cutting all the way through the material. For both of these issues I have been using a 45a FineCut cartridge and have been cutting a range of materials from 14ga to 11ga. I’ve noticed this issue mostly happens on outside contours, after it has successfully completed clean interior cuts.

Few notes about the most recent time this issue has happened (today)(Pictures attached)

-I cut the entire interior of this 11ga sign with no issues, using 45a fine cut cartridge

-When it went to cut the final outside contour cut, it pierced, cut clean for about 4 inches then barely penetrated the material for the next 8 inches.

-I was not paying attention to what the torch was doing when this happened so I am unsure of what the torch was doing (voltage, height ect.)

-After this happened I tried to run it again & it did the same thing, I then ran the program until it was done while it was intermittently making full penetration around the outside of the material.

-After the program was completed I immediately generated 2 straight line cuts around the sign so I could remove the sign from the table, these cuts were at the same IPM as the last outside contour cut. These 2 straight line cuts, cut perfectly fine with full severance of the material and virtually no dross at all.

A few other things I have done,

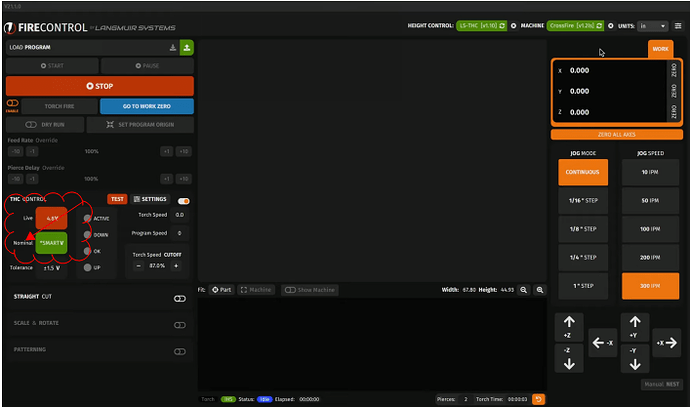

-Ran THC tests in fire control 2 separate times, these tests passed with no issues.

-Drained desiccant filters before cutting.

-Verified 110 PSI to plasma cutter

-Checked all cable connections from CPC port, to THC box, to the table computer and all connections to the touch screen.

-Verified all contours in sheetcam are under the same Plasma Cut Operation

-Ground clamp is always directly on the material

-Cut settings are per HyperTherm manual

Similar things associated to these two issues,

-Both issues occur when using 45amp fine cut cartridge

-Both issues only occur when using third party dxf files (Etsy, Fireshare, PlasmaSpider)