Trying to get my everlast 62i set up in fusion and the video must be old… the tabs in fusion look different

Are you asking how to create a tool setup in Fusion? If so, here is a video from Langmuir:

I have watched that video.There is a very big difference in the fusion that i’m looking at.

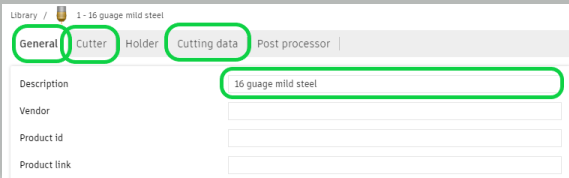

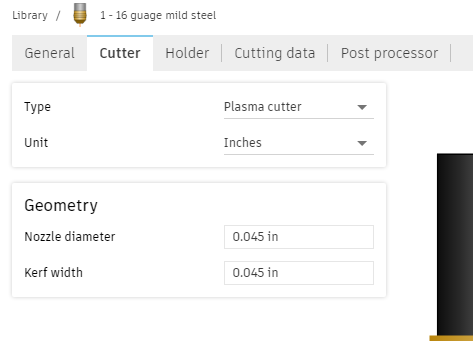

Setting up tools (Plasma) in Fusion is rather straight forward. Under the cutter tab, set your kerf. I like to set my Nozzle Dia to the same value. Under Cutting Data, set your feed rate (IPM). I tend to use the same rate for lead in/out but some will suggest otherwise. I’ll additionally add the Pierce / Cut heights & Pierce Time, but the default Post ignores these values. (You’ll need to add them when Post Processing.) Under Post Processor, give it a unique #. (Fusion does like multiple tools with the same #.)

Terrance (@Simsworx ) gave you lots of information but it is all very good information.

You are entering the area that gave me the most fits (Manufacturing) so don’t give up. We all went thru it: and survived. Just set up one or two tools and then when you have an actual sketch you want to take thru the CAM process (manufacturing) it will make more sense. We will all watch out for you and help you thru it.

You only need to enter things in these three tabs (General, Cutter, Cutting data):

Cutter:

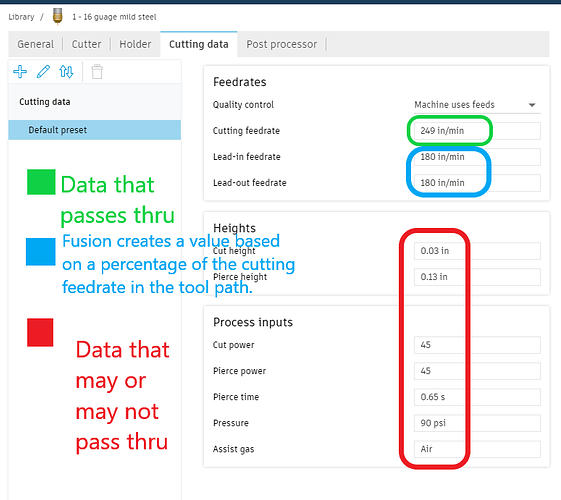

Cutting data. Many of us have been filling in all this detail but little of it flows to the post processor*:

*There is currently a team of people looking into this and hopefully will have a post processor that uses the most important elements of this “Cutting data.” As of Dec. 2023, much of this data needs to be manually entered in the final stage of post processing in Fusion 360 even if you entered in the “tool.”

@Simsworx is part of that team. I only sit in on the meetings to see if anyone brought any snacks.

@ChelanJim provides great information, as well as illustrations!

I will say that as you progress, you’ll want to set up a “tool” for each of the materials you cut. I currently have 20ga thru 1/2" setup (for a RazorWeld Cut 45). The only reason is to define the kerfs and identify what cut speeds are good for the material. The mfg’s cut sheets are a good starting point, but often a little adjustment needs to occur.

As you progress and can identify problem areas, it’s easy to identify and correct based on material thickness.

Good luck!

Thank you as always the information is helpful.