I have been having problems with holes not cutting square all the way thru the metal. My understanding is that the torch should slow down in holes to accommodate this concern but watching fire control during the cut and it does not seem to be slowing down at all. Am I missing a setting?

I have clean dry air.

I have new consumables.

I’m using a Hypertherm Powermax 45xp.

I’m using the settings for best cut from the HP manual.

My table and torch area all leveled within .1 using a digital level / angle finder.

Depending on which CAM software your using there are options to slow down the cut to improve bevel.

In Fusion 360 it is call Feed Optimization. It is location in the 2D profile menu.

Thank you. I will try this!

check your actually cut height verse the one you wrote into your post, some times it is higher then you want. I set my cut .02 lower in post to get a true cut height on the table.

this can help bevel too.

Quick question so manipulating or changing a burn profile sequence, Fire Control pro cannot overwrite a sheet cam G code to slow down a non programmed slow down ? I think sheet cam is 60% slow down for holes std.% ? K, XR due Aug.

Think I get it do all the big work in sheet cam or fusion dump it to the interface that is suited to the motor controllers and human interface for cutting. This 2 step process seems a little off to me but I can deal with it for now. .

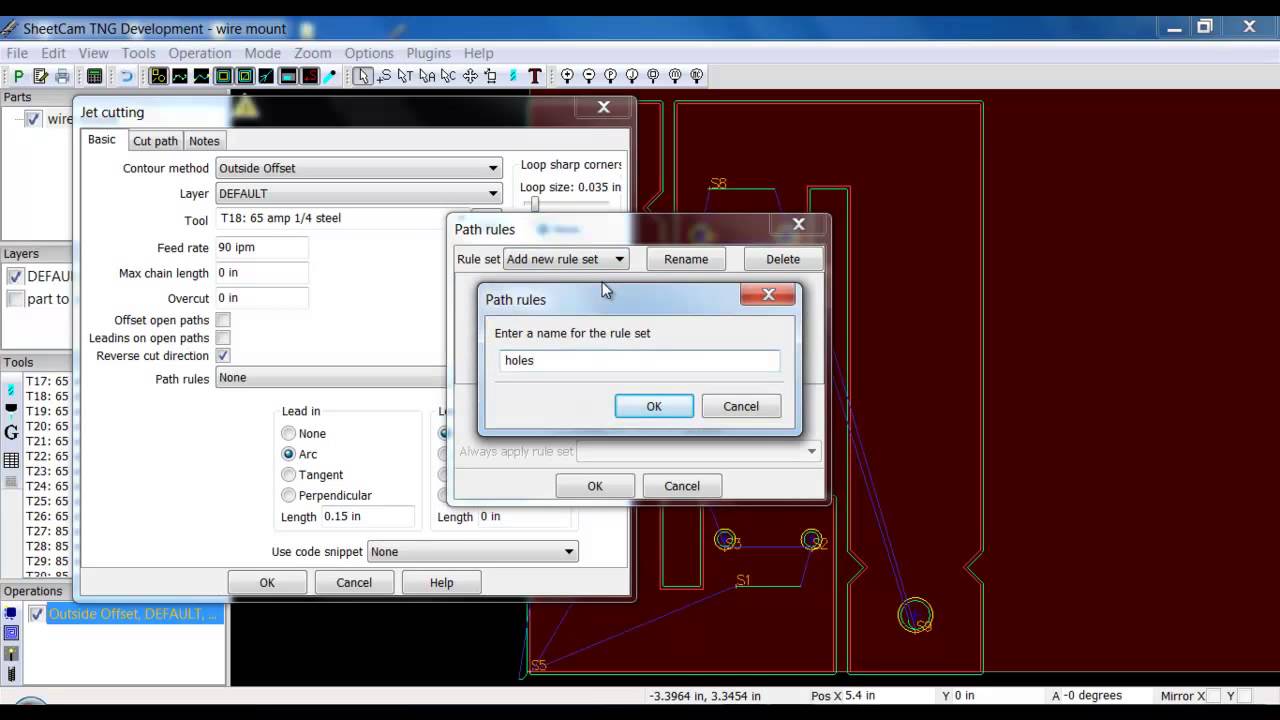

In order to slow down for holes in Sheetcam, you have to set a “path rule” that specifies what type of cut to slow down for (holes, sharp corners, curves) and the percentage of the programmed feed rate to slow down.