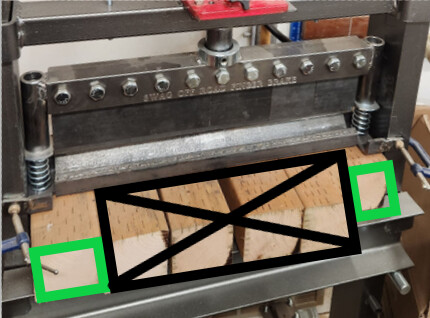

I don’t think those are helping as much as 2 laid perpendicular to the way they are would. They’re not adding much to the beam resisting the deflection of the die flexing since they move independently every 4" (or 3.5")

You might be right but they are only spanning the 4 inch gap that the press leaves. That swag brake lives right in that gap. My point was that if there was a gap left in the middle and I only had two solid supports (you pick the material) in the locations marked in green, there would be a chance to have that bottom part of the swag brake bend. I could not see it getting enough deflection to bend if it was supported in the center.

Color me dumb, what was the reason for supporting the whole setup under blocks?

You mentioned it as possibly the reason for being unable to bend a 6" wide piece (easily) in the center and having trouble with it.

I never had any issues bending anything in my old brake, and if the material wasn’t the full width of the brake, I would always use the center.

You are getting the posts confused. Sticks mentioned:

Then you said:

I was merely stating, I could see how it would could get bent. I am not having issues with my setup but I have not done any 3/8" but have done 6 inch wide 1/4" plate.

Sorry @ChelanJim

My initial response was towards this specifically -

“I can confirm that 1/4 inch and 6 inch width is pushing it on the 20 ton” by Sticks

That’s why I kept referring to bending 1/4" at 6" working width, and why I posted an item over 15" wide at 1/4" thick.

To which you stated you run 2" x 4" underneath your brake. I never ran anything underneath outside of the factory setup.

I see now you’re referring to the press brake itself? I was only talking about the material being bent. Apologies for the confusion.