I get a TON of smoke when I cut. Is there something I can do to cut that down? I’m cutting 1/8" sheet at 200 in/min at 45 amps on my hypertherm 45xp.

Are you using a water table? If not, I highly recommend you buy/make one, or cut outdoors.

I ordered a water table but it has not arrived yet. I didn’t know that would help with smoke or exactly what it does. I have ZERO experience with this stuff and I think I’m actually doing well from where I started

You think the smoke is bad now? Wait until you cut stainless.

The water table will trap a LOT of smoke, but not all of it. I also have a hose hooked up to a fan that is mounted to my gantry that blows outside and a fume extractor that sucks up smoke from the side of the table. And yet I still get smoke everywhere sometimes. Just be careful and air out your shop often

Keeping the water up to the plate is perfectly fine as long as it’s NOT aluminum. Steel and stainless cutting are find but do NOT cut aluminum with a high water level.

Hell I just cut some stainless steel under water and it was great

Follow up… I received my water table today and didn’t waste any time installing it. I cut a piece out using just water and I was ABSOLUTELY AMAZED how well it did with the smoke and dust. I’m sold on that for sure

Wait, 200 in/min with a 45xp?!

75 is the fastest I’ve run mine with 10ga and that’s stupid fast I feel.

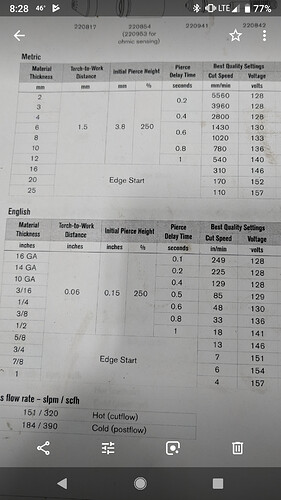

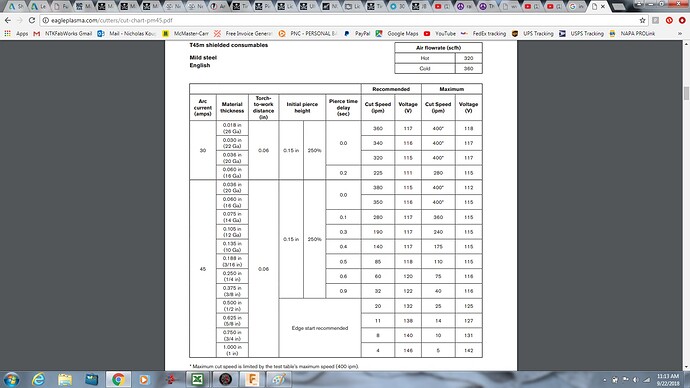

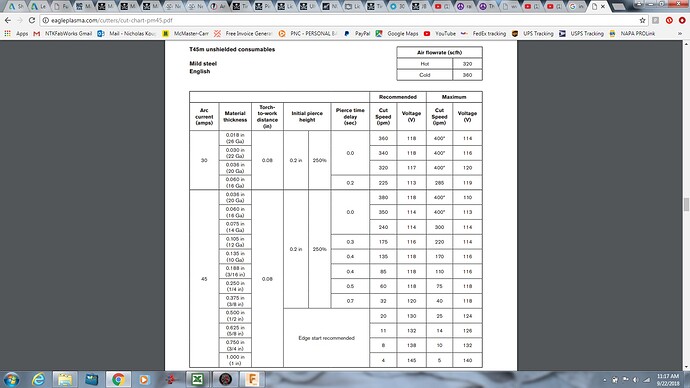

Your chart says 135 inch/minute for 10 gauge at 45 amps so why would you go slower?

Because it was leaving a less than desirable kerf angle, which once ground square, threw off my tolerances