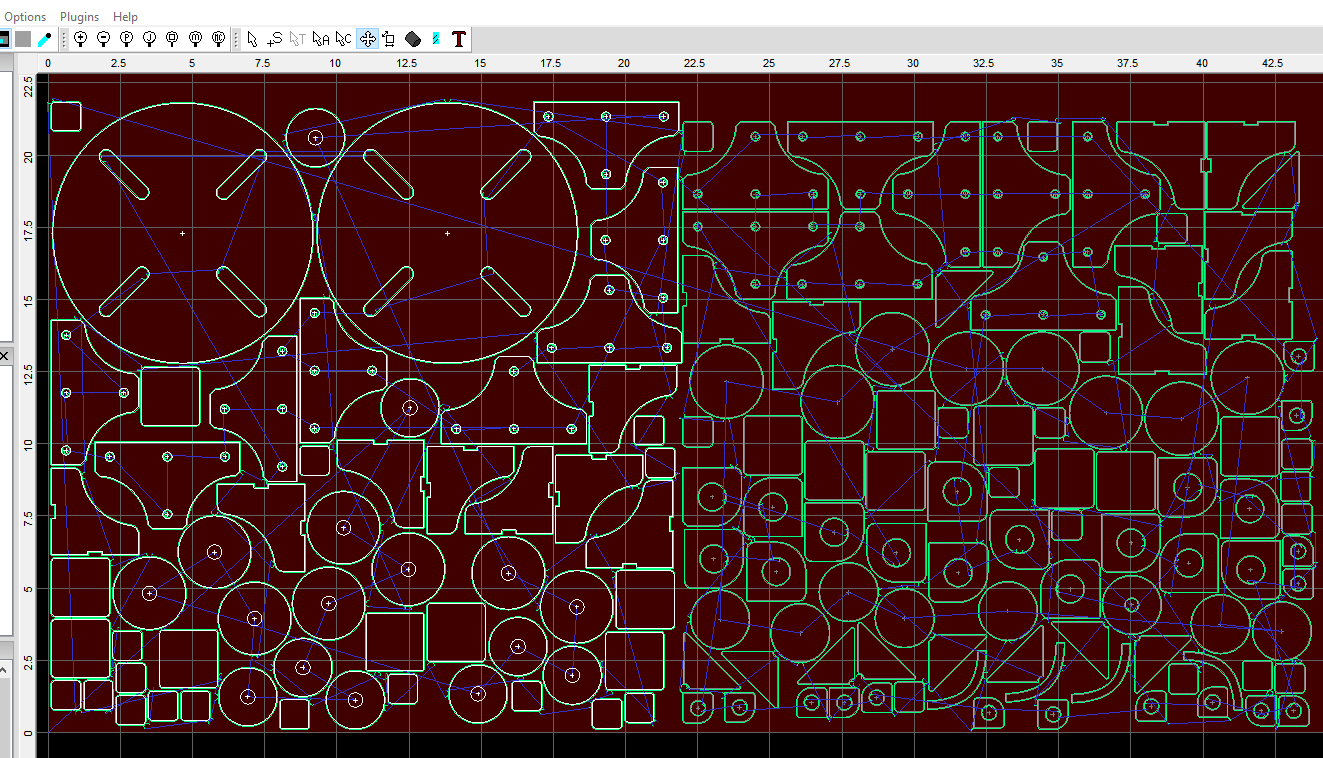

Was working on some brackets and parts today for some upcoming projects - thought I’d share it as it’s the most complex nest I’ve ever done and should give my table a workout. It may also help someone trying to do this. I used deepnest.io and sheetcam after designing the parts in Fusion360. So far, for me, I’ve found F360’s nesting is not as easy to use as deepnest and sheetcam. Sheetcam also has some basic nesting capabilities on it’s own by duplicating parts in arrays or you can hand arrange pieces using the nesting menu item - this might be enought if you just want to duplicate a part a few times. Firecontrol* is also coming to the nesting party as well from what I’ve read - not used it yet though.

But, for my use, the best combo has been F360 or Illustrator/Inkscape to design parts → Deepnest.io → Sheetcam → Firecontrol

The basic process to generate this:

- Design part as sketch in F360 (or any design software)

- Save sketch as dfx

- Deepnest.io → Import - do this for each dfx you want to add to nest. I had 15 individual parts in this nest.

- Specify quantity for each part

- Add a rectangle (in my case 22 x 22) - you do this by clicking the + button at the bottom of screen and entering dimensions. Once it’s added you MUST click the Sheet checkbox. This tells deepnest that the rectangle is the material you are going to be nesting the parts into (your stock or sheetmetal to cut from).

- Click “start nest”

- After a few iterations, it will have found a good nesting pattern.

- Click export to SVG and save the file (add .svg extension).

- Over to sheetcam - import the svg (use 1:1 scaling)

- Setup your operations like you would any other sheetcam job and post it.

- Over to firecontrol to start cutting!

A few steps, but the results are pretty incredible if you ask me…