Go with the Everlast and never look back. 52i, 62i,or the 82i. Wire it for RAW voltage, and you’re done.

But what about limit switches? You haven’t said anything about limit switches… ![]()

Nobody is listening, Tom.

@Tryin ignore the comment about the limit switches. That is a longstanding running comment to speak ill of the poor little “limit switches.” This will illustrate all you need to know about limit switches:

Ok I will go with the 52i for now. I will also use the raw voltage. Thank you all very much for your help!

Good choice. Never look back. Suppose your table or business outgrows it. You can put the hand torch on and use it in your shop.

Sounds like @TomWS hit YOUR limit switch. Lol

I don’t even have limit switches… and he has hit mine from time to time. ![]()

![]()

YES! I am INVINCIBLE!

I’m saving this chart. The Primeweld chart doesn’t have all the thicknesses and what I’ve figured out for the missing ones kinda lines up with this chart. It will be handy when I cut a thickness for the first time.

It’s right on for the Everlast 82i. It will put you in the ballpark for sure. Now, the Stainless section is based on F5 gas. When I cut SS, I use this instead of air. But it’s still very close.

I’m just a hobbyist (and usually doing thinner stuff) so it’s strictly air for me.

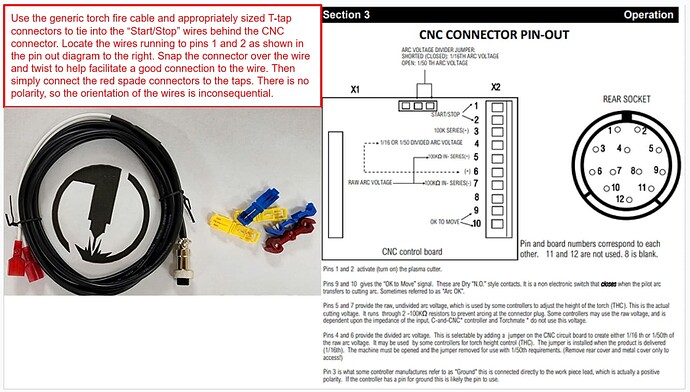

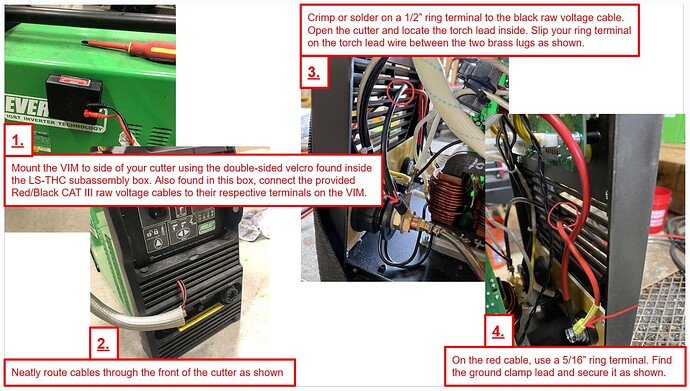

I got the Everlast 52i and hooked it up just like the picture shows, and it seems to be working well!

Excellent!