Ok so I have to ask, what have you found this to be the cause if you remedy it and it comes back suddenly?

Please read below -

I cut 16 gauge up to 1/4" nice and square, achieving square cuts on both the X and Y axis.

I cut circles, slots, and full figures in the appropriate manner IE clockwise outside, counter clockwise inside.

I perform table maintenance every few months, not to mention knocking dross off the slats.

I ensure my torch is square to the work piece, not to mention having squared up my gantry tubes again just 2-3 months ago.

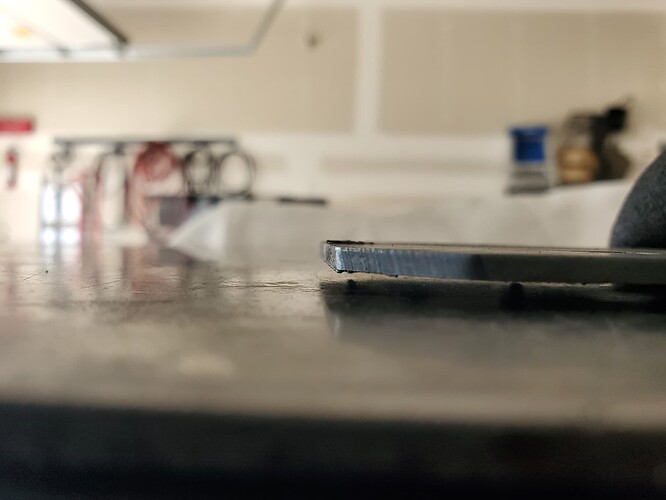

Knowing everything is square, and using previously used cut files I’ve created, using the same cut settings I’ve used before, why would one suddenly achieve beveling alongside one edge but not the other opposing edge that runs in the same direction?

I cut some 16 gauge ghost ornaments yesterday, and got beveling along some inner and outer edges (not all but some).

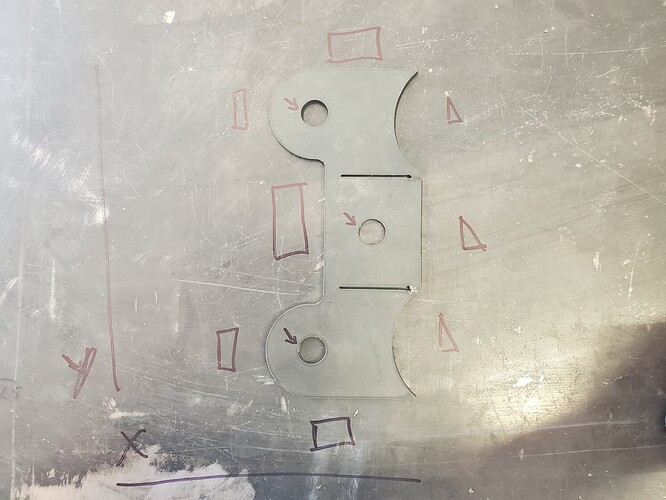

Today I cut some 10 gauge which will better depict the issue most; the “square” shapes means those edges are square and the “triangle” shapes means those edges have a bevel. The holes also have beveling noted by the arrows which correlates with the edge that has beveling -

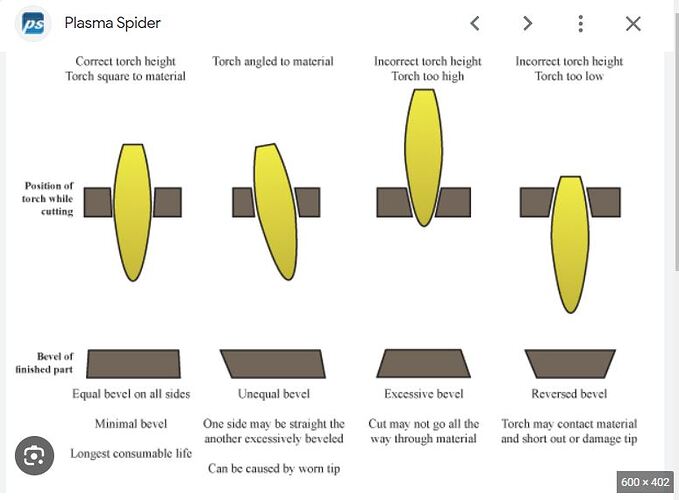

Again, I do understand how beveling occurs and normally how to remedy it.

Beveling all around would mean incorrect cut height. That is not the issue here (generally speaking).

Beveling in one axis would mean the torch is canted ever so slightly in the mount. It is square all the way around in relation to the work metal it cuts into.

Beveling in one axis would mean the gantry tube in one axis would be out of square. Jogging the torch from one end of the axis to the other depicts roughly 1/32" of an inch of deviation and THC would easily account for that.

So unless I just disassemble to an extent and reinstall it all together again, I’m unsure what part exactly I should be looking at?

No, it’s not a coupler issue or binding. My couplers and shafts are marked and the marks are still matching.