hi

No, I just let it drip into the coffee can! One of these years I will embark on the “great leak repair project” OR, if the leak gets worse then I will go into the “leak war” mode (me lazy?? well possibly)

and truthfully, I did not think of JB weld)

I had a leak about 6 weeks from the time of my build. I didn’t use JB Weld either, just giving the youngster KwikFab a hard time!

I used this product on the topside and bottom-side of the seam of the pan.

It doesn’t look pretty but no leak for 3 years since that repair.

Y’all just need to learn how to weld ![]()

That is probably what the Langmuir designers of the pan thought, as well.

But just thinking out of the box wouldn’t a better system (short of a one piece pan) be a flat joint with a clip lock piece: similar to what is used by the HVAC people when joining ventilation sections together. A bead of caulk, snap lock it together and done.

He is never going to stop, there is only one fix in his book🤣

Cause welding is easy ![]()

NOPE!!! ![]()

![]()

Who were we talking about? ![]()

Don’t be ridiculous. You would use double stick tape.

So much to teach you, so little time. ![]()

Is that like folded over duck tape?

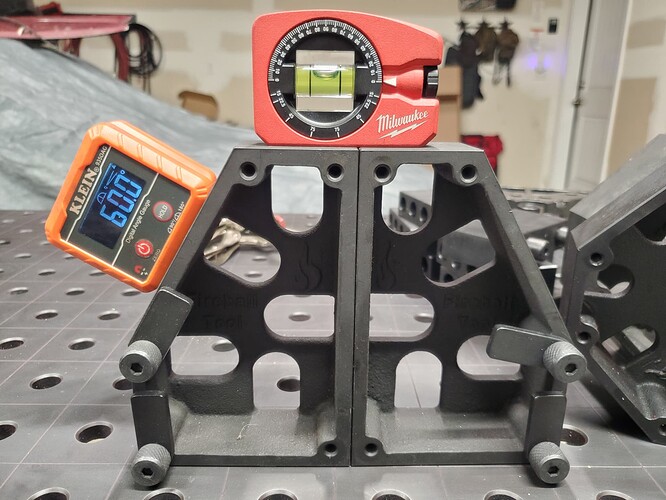

So I am curious why are there 2 legs right next to each other on your table?

I usually end up placing heavier objects on that side of the table more than the other side.

Not to mention I normally sit on the other side where it’s open, but I got lazy since I was running parts on my press brake and welding them shortly after.

The legs in the center just add support as my tables are level all the way across.

Pics I took a couple of weeks ago (he was asking about fixtures).

But getting the correct angle for parts is important to me, not just angles in relation to parts they’re welded to but on my table as well.

See, you are all ready thinking of how you can use JB weld.

Haha, it’s funny how my little mistake sparked such a lively discussion. Honestly, I’m still not sure what’s so unusual about JB.

@72Pony, really loved reading your story!

My “little mistake” before I TIG welded mine makes yours look tame. I initially tried the sealer provided by LS. I probably tightened it a little too tight, or missed a spot, and got some tiny pinpoint leaks.

My brother-in-law has been involved in commercial bldg roofing for Firestone for about 40 yrs. He told me he could lay a 6" strip of rubber over the seam and it would never leak. 6 months later, he was proven wrong. The torch never damaged the rubber. I avoided cutting over the seam at anything more than 40 amps, which is rare for me anyway. The water finally made it’s way under where the rubber turned up the side wall of the tray.

Talk about a mess removing that sealer ![]()

I fusion welded it with my Primeweld TIG welder about a year ago and all good now.