Has anyone thought about making their own drains for the table? Would be interested in any ideas. Thinking about doing it to save a few bucks.

we talking the 80 buck drain kit? i havent found anything yet, but for the price its not all that bad.

Yea the $80. Im cheap so thinking of designing my own.

yea, you could 3d print something or even use some basic floor drain setup. I plan on modding mine also once i get it, more so to put a tool box under it.

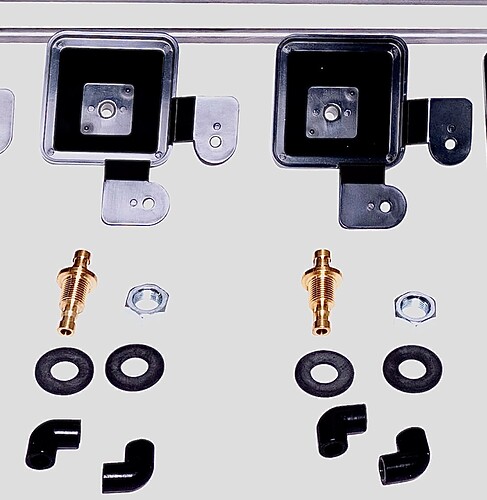

I have similar issues with the drain kit. It’s a good deal for what you get but the screens look like they’re only 3x3” and the plumbing is about 1/4”. Correct me if I’m wrong.

I don’t like the exit location or that the plumbing is encapsulated by concrete so I just bought some fine mesh stainless screen that’s big enough make (4) 5x6” drains. The plan is to fit common, easily removable and reusable coffee filters for additional filtration. These only cost $3-5 each.

Exit coolant at the corners and add 1/2” nylon tubing directing the 4 of them to the rear.

I just need to design it and have access to a 3d printer.

yea those would work, i see they make a lot of nice stainless funnels with filters too. might be worth it, and make it drain below the base so its easy fixable.

after watching more build videos, @langmuirsystems any idea why the exit is on the center vs drain right below the cups? I would think if you drain it directly down with all plumbing under it it would keep anything from maybe having issues in the future encapsulated in concrete.

Thanks

If your time is worth anything don’t try to DIY it. Just pay the $80 and move on. You’ll end end up spending $40 on parts and multiple hours trying to source all the right parts. Dont to mentions trying to cobble it together. Keep in mind it’s getting burried in concrete too.

my issue is the berried in concrete part lol. i dont mind buying the kit, but i dont get why they cant just drain down vs that jog in the concreate.

Fair enough. But think about it, even if they leak or clog you can fix it. If they leak, its surrounded by concrete so it will keep flowing. If they clog you can just air blast it. or fish it out

I’m not that cheap. I want to run multiple coolant nozzles and just don’t know the flow rate of those tiny drains. A single nozzle will probably not have issues but if all you really want is one,

you surely don’t need a 2000gph pump to feed it.

I messaged them about this. They never gave me a straight answer about the GPM capability. Although usually you want two nozzles for different height tools. And since we have to do manual tool changes we’ll be adjusting the coolant after each new tool.

At zero head, the coolant pump has a rating of 1800 GPH without any hose connected. The feed hose is 3/8" of an inch feeding into a 3mm nozzle with a feed hose length of about 4ft off the ground. The limiting factor isn’t the pump, it’s the drains. With just one nozzle connected, the pump is mostly recirculating back into the tank. You can certainly connect another locline nozzle and the pump can easily keep up but then the drains will not be able to drain fast enough. Hope this helps!

Brian we are on the same track. Im building my own coolant system drains included. I am also planning multiple coolant nozzles to help flush any pockets to keep from double cutting chips. Also adding a wash down hose. Wont have the design totally figured out until the machine arives in a couple weeks . Probably going to be formed and welded aluminum with at least 1" return lines

I’m trying not to be too critical. I just don’t see the logic in it all. Why put 2 90 degree bends in a drain system rather than go straight down? And when I say tiny…I mean tiny. The tab holes are for 10/24 screws (.190”) the gaskets have a .615” ID so how small are the holes in those brass outlets?

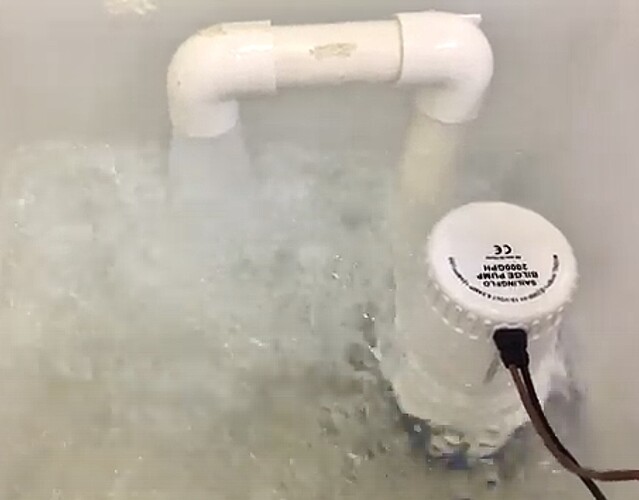

The LS coolant system pump says 2000gph right on it. The outlet size is 1-1/2 to 1-1/4”. All that to feed a 1/8” coolant nozzle? I have a 1/4hp sump pump already and it’s rated 8 amps. I also have a $13 aquarium pump with 1/2” outlet that flows 200-400gph and it uses only 25 watts. No dedicated circuit required. Also have a couple fountain pumps that flow 900-1500gph range so I have several options.

As mentioned, I bought some stainless screen material. The mesh is just under 2mm so probably comparable to the LS screens. Hopefully I can design the perimeter to snap in place like Tupperware so they stay secure. Also went with metal screen coffee filters thinking they would hold up better than nylon. These have a lip near the top that will prevent them from dropping down and lift handles making them easier to remove for cleaning.

let me know how those other pumps work. this is one of those things i wondered about. I dont mind buying the kit, but i also want to add a sprayer and larger drains.

I HIGHLY recommend the sprayer!!!