That definitely worked by inputting values in milliseconds (ms) in F360 and keeping the box checked for milliseconds in Mach3

Okay that’s weird. It’s not the “delayed start” issue. Are those bits dross stuck to the sides of the cut or raw steel that’s not cut?

To me it looks like uncut metal, like if the torch stopped before it reached back to the starting point, but will see what he says

But half the kerf width is cut. That’s what’s weird.

Almost like if the drawing of the lettering isn’t fully closed if that’s possible, or lead screw slippage and missing some steps but doubtful I dunno weird

Hi James!: its raw steel uncut. not even a mark like a a pierce that did not make it.

Hi CHUCK: its lead out that you see.Its like the lead in did not happen… if you follow the rules of rotation of outside and inside cuts the lead out is perfect. Im going to try the nano seconds for the pierce , but if thats it, then all my tap files will be trashed…ps:.Ive had slippage in the past that completely screwed a project so the dogs that held the lead screws are long gone and its drilled through and a spring pin put in place so slippage is no longer possible.

Great news. Rely weird manifestation of the Mach3 bug though.

Probably something @langmuir-daniel might want to add to the official installation & setup documentation. If you’re running Windows 10, you need both the patch file they have on the download page but also the config change for G04

Good shit! I encountered some weirdness to from a loose lead screw and what I now know was pierce delay related on some of my testing having really cut no realy parts except for some 3/8" brackets that turned out spectacular (on those particular ones I recall changing the MACH 3 to seconds versus milliseconds) and then I dunno what happen im a newb to CNC let alone CAM/CAD I have literally 2 weeks of experience with this stuff but its fun, but mostly been playing on some 16g mild steel getting it dialed in moreless, pain in the ass when I need to change dimensions and re-post everything but its making me more familiar with it all

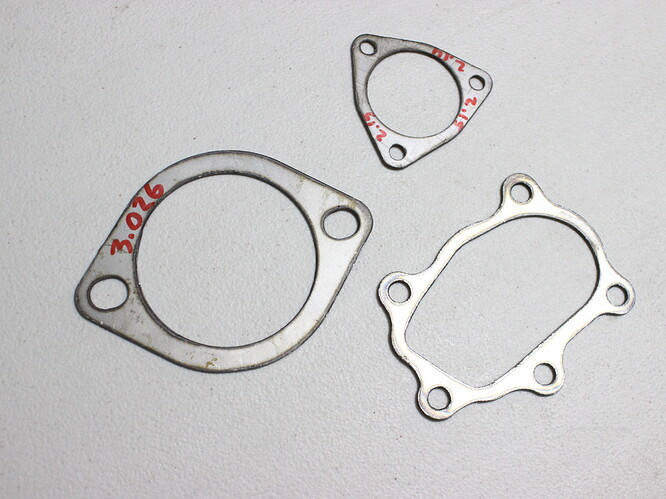

Some shit I been doing today, glad you figured it out tho! ![]()

What are your speeds, tip clearance, and amps for the thin 16 G mild? I haven’t had alot of luck with thin materials yet. I’ve done some. 060 stainless but had major dross…

Do you still have the Automation stuff for the 625X?

I think so, be tomorrow evening before I can look for it though.

I’m still interested in the Automation stuff for the 625X

Found it, are you still interested? If so I will take pics and email if you would like.

Keenly interested. Do you use Paypal?

Yes I do,

Contact me thru islandweld96@gmail.com.

Easier for me to communicate since I’m not on school computer.

Hey Chuck so i have a miller 625 just like yours. The torch wiring was very helpful so thanks for that. Just curious do the black and red wires need to be connected to certain wires of the plasma? So here’s my issue i connect them plug the port into the langmuir box and when it first makes contact the torch fires and stays on. If i plug it fully in the torch goes off but does not come on when you run the program. Any insight would be greatly appreciated.

THanks

Matt

Black and Red? take a picture I dont recall Black and Red wires but its been a while

Not in the machine of the plasma. The cable that has the connection port that plugs into the langmuir system box and the the other end has the 2 wires, one red and one black that will get spliced to the plasma to 25A and to 26 as per your diagram.