HI all,

I’m very happy to say that I cut my first couple of pieces out today on my Crossfire. It took me a lot of time watching and re-watching the YouTube videos by Langmuir, but finally thought I had my ducks in a row. I had some scrap metal and wanted to do a sample cut for myself before cutting/wasting heavier metal. I used Fusion 360 to design my part, an axle tab for 4 link suspension, created the plasma tool type, generated a tool path, etc, and saved the file to my laptop. I uploaded the G-code to Mach 3 and began the cut. I’m using a Razorweld 45 Amp Plasma cutter at 45 amps. The torch fired and cut my tab out of 14 ga mild steel sheet. It was very exciting to see the Crossfire at work, but when it finished cutting, I noticed a big problem with my tab. It seems that the torch was firing along the entire tool path and put a big slice right through the middle/side of my tab (See Picture 1). I then decided to cut another one and without changing anything in Mach 3 or Fusion, the cut came out better but I have a notch where the torch starts and stops. (See Picture 2). A third cut duplicated the first problem with a slice through the side. Can anyone advise me on what I’m doing wrong or what I need to adjust? Why did it cut differently between the three different rounds of cutting?

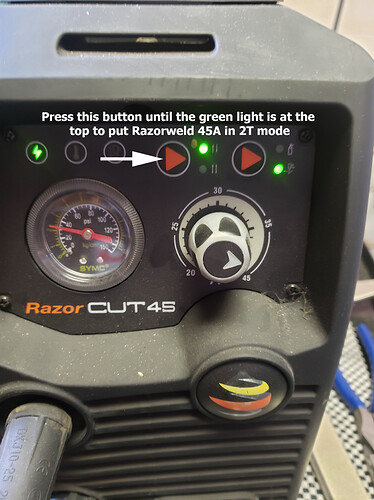

look on your plasma cutter for a 2T / 4T switch and set it to 2T. I think I looked this up for someone before and posted a picture of their control panel if you can’t find it, if you care to search .

The notch where the torch starts and stops is referred to as the pierce and when it starts and stops is the lead-in and pierce delay (how long it stays there). Javelin is correct in that you probably have your machine set to 4T.

You should make sure your outter cut paths are clockwise and your inner cut paths are counterclockwise. As well, your cuts should have a long enough lead-in where that ‘hole’ or pierce is less noticeable. I use Sheetcam, not Fusion, so I’m not sure where to tell you to change or input those values in Fusion. In some cuts you may not have a choice, because it may be too tight of an area.

KX9M (Bill P) explained this very well to me once on here - so if I’m screwing this up, reach out to him, he’s a huge help - as well as many other members.

Gunny

Problem Solved! Switching to 2T was the fix. Got a great clean cut and am super excited to start using my Crossfire! Thank you for the very fast help. This forum and its members are awesome!

Lets see your car project!

I’m having the same issue you had, how did you switch it?