I stand corrected. I was thinking of hardening and tempering together. My point is stop after annealing. Since @Coppersmithcustoms indicates he plans to use 1095 it’s probably worth looking at the tables for that material.

Yup. I’ve got one of his kits. Great unit, but without a quality motor and VFD, it won’t shine.

You build it yourself. I purchased a 2 HP three-phase motor with Hitachi WJ200-015 VFD.

The thing will flat-out eat metal.

It is the best kit I have seen. Not the cheapest.

Yup. I’ve got a lesser expensive 3 phase motor, but on a TECO Westinghouse “Wash-downable” VFD with all the fixins. Amazing units and I don’t use 99% of the features, but SMOOOOOTH operation and control.

The Cement base adjustable height stand is also a must if you need mobility for the VFD.

1095 would work just fine on the crossfire. I’ve cut it on my crossfire as well. About 1/8" all the way around the parameter will be super hard and brittle. That area will could chip off. When I make knives using the plasma table I oversize it by about 1/8" all around than grind that part off.

If you start with hardened steel then cut it on the plasma the hardness will get all messed up. If you want a hardened blade you have to heat treat it after cutting. When you harden high carbon steel it gets into the low 60 rockwell, and is so hard it will break super easy. If you then Temper it it will be super strong. To temper 1095 you need to put it in the oven at 500 degrees for 2 hours. This will bring the hardness down into the 50RC rang. Now it will not break. You can even do two cycles of temporing to make it even less likely to break.

Lol. There are no simple answers here. Ask what 2+2 is and we will eventually be talking about mathematical theory and start questioning the universe. And I love it.

Do you see any benefits of 1095 over 1080 for what he’s trying to do? The only real benefit I can see is that it’d be able to reach higher Rc, but it doesn’t sound like he cares much about how hard it ends up just so long as it’s tough. Going above the eutectoid point of about 0.8% carbon is only useful if your goal is to have leftover carbides after hardening and tempering, and since wear resistance isn’t a big deal to him, I’m wondering if it’d be giving up toughness for hardness he doesn’t need.

It does not need to be 1095. I was actually doing some more research and wondering if 1077 would be better.

I think that is where i am. Hard enough that it will hold an edge but not to hard that it shatters when it lands on the concrete.

Lol. My shopping list for needed equipment has definitely grown. I also need to find a source for the sheet metal.

2 is an interesting number. It is one of the most essential numbers in mathematics. It is the only number whose product is equal to its square… it’s also the only even prime number.

Maybe only zero is more important than the number two… I suppose that is debatable. My differential equations professor was from Turkey… and was always preaching how important the number zero was… He called zero Mr. Zero. He took a month-long trip to Europe in the middle of the semester. When he came back, he brought us a picture of him standing by a zero that was like 50 feet tall… well I guess it was probably 15 meters tall: ![]() Anyway… I wish I could type with a Turkish accent while telling the story… I’ll try… you will just have to read it that way. He said " while I was traaaveling through Gerrrmany I came across the most BEEEEAUTIFUL Zero in a field. The Gerrrmans understand the eeemportance of Meester. Zero!" He passed copies of the picture around the class. I was sitting at the back table and slipped the picture inside the front sleeve of my 3-ring binder I used for the class. Every day I came to class I would stand the binder up on my desk facing the front of the class. One day a couple weeks later he finally noticed his picture in my binder, and he stopped mid-sentence in his lecture and said, “YES ERIK YES!!” I barley scraped by in that class… I credit keeping Mr. zero close by to help me adsorb the course lectures!

Anyway… I wish I could type with a Turkish accent while telling the story… I’ll try… you will just have to read it that way. He said " while I was traaaveling through Gerrrmany I came across the most BEEEEAUTIFUL Zero in a field. The Gerrrmans understand the eeemportance of Meester. Zero!" He passed copies of the picture around the class. I was sitting at the back table and slipped the picture inside the front sleeve of my 3-ring binder I used for the class. Every day I came to class I would stand the binder up on my desk facing the front of the class. One day a couple weeks later he finally noticed his picture in my binder, and he stopped mid-sentence in his lecture and said, “YES ERIK YES!!” I barley scraped by in that class… I credit keeping Mr. zero close by to help me adsorb the course lectures! ![]()

![]()

![]()

![]()

No it does not need to be 1095. Anything between 1095 and 1045 would work just fine. 1095 and 1084 are prolly the biggest bang for your buck. Those two are the most common in the knife making community. So you’ll be able to buy them lots of places, and it lots of different sizes.

sheets are gonna be hard to find but you can get bar stock lots of places. The guy who runs this website is a personal friend. I can vouch for him. High Carbon Steel (maritimeknifesupply.com)

He should definitely look around at some other vendors too, even if maritime has great pricing. Some places sell stock for a price based on what they paid for it, and some places price it for current market value. Whether prices are going up or down there’s usually an outlier or two on either side of the average price if you’re looking to squeeze every penny.

A great relationship with your supplier matters more to guys who need to get material regularly than a guy making a few one off knives. Consistent stock is a big deal if you’re doing volume.

ok to recap. I see some info on here that needs clarified.

Annealing is something you do to take all the hardness out of the steel, and making it as soft as it can be. If you’re going to do that then just use 1018 or A36 mild steel.

Tempering is something that you NEED to do if you heat treat the steel. If you heat treat 1095 or 1084 you’ll end up around 60 - 62 RC. The knife might crack just setting on the counter top. It is important to “temper” a heat treated knife within and hour or two of heat treatment. Until it is tempered be careful with it. Do not drop it! This releases the stress and tension in the steel and makes it very strong. At tempering cycle only takes you from 60-62 RC down to maybe 58RC which is still very very hard.

Tempering 1084 at 450 for 2 hours only takes it down to 59-60rc this is why I suggest 500 degrees for 2 hours. Do two cycles of this let it cool completely in between. This should take the RC down to around 55 if you’re lucky.

If you want something softer do the same heat treat and tempering but use 1045. You might get down into the 45 RC in that case. If you just want something super impact resistant use 4140PH. You can make hammers out of 4140PH

“Great job, Richard! Your insights are very interesting and informative. Metallurgy seems like voodoo to me.” @Richarddbeck83

So Richard, I will admit that I know just above the “nothing” level on this heat of metal. I described this in another thread but expected that I might be using terms wrong. I made a stationary blade for making kindling. In summary I described annealing because the metal was hardened after cutting with an abrasive blade and too hard to sharpen with a file.

I heated it to red hot (annealing) to soften. Cooled to room temp. Easy to file at that point but did not hold the edge.

I then hit it with a propane torch to turn it blue and tried to keep it there for a few minutes. I allowed it to slowly cool in a very warm room (about 85 degrees). It was then able to hold the sharpened edge much better.

What did I do to that metal? What would that be called?

Even annealed, 1080 or similar high carbon steels will have a higher hardness, tensile and yield strength than 1018, so it’s technically not a total waste, but I agree that if you’re going to go through the effort to make the knives they should at least be hardened and tempered to a minimum of 50Rc, otherwise you might as well just buy cheap knives off of the internet, as they’ll perform the same or better than a custom throwing knife made from annealed steel of just about any grade.

1080 at 50Rc can still probably be bent at almost a 90° angle even with a less than perfect heat treatment, and will stay sharp for ages compared to anything that has been annealed.

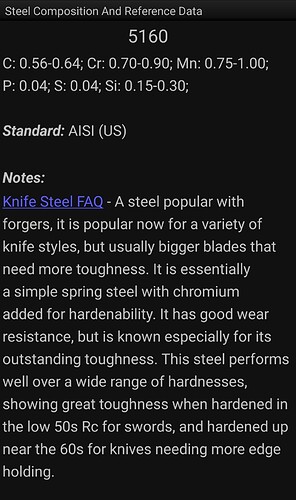

I mentioned 5160 in one of my first posts as a superior alternative to 1095 for his use case. I think if he’s looking for something tougher for a throwing knife, it may be an even better choice than 4140PH because it can get a little harder while also being tough as an old boot. 4140 at 50Rc is tough, but I wouldn’t expect much for edge retention (or in this case, tip sharpness) with only 0.4% carbon. Not saying it’s a bad choice, just that 5160 may be a tiny hair better since either is probably more than tough enough.

Yeah I wouldn’t normally use 4140PH for a knife but if you’re just looking for something to be throw and beat up than maybe it would be a good option. I agree 5160 is a great choice. I just wouldn’t go to the trouble of using high quality steel if you’re not going to heat threat and temper it. That kinda defeats the entire purpose of why these steels were developed in the first place. There are a lot of steels that are better then your basic high carbon steel but I don’t normally recommend those to guys who are new to knife making. I try to start them off with something that’s easy to find, easy to heat treat, not crazy expensive, and pretty forgiving and idiot proof. ![]()

heating to red hot and letting it cool could be considered Annealing but it might not be depending on the steel you do it to. Red hot and cool slowly would be considered thermal cycling or normalizing. This is a good for reducing the stress in the steel. Yes it will soften the steel but it might not be completely softened to an “Annealed” state. Annealing is a very specific process that requires you to hit a specific temp, hold for a specific time, and cool at a specific rate. This guarantees that the steel is a specific RC.

If you buy steel that is annealed you can normally bank on it being a specific RC. So did you “anneal” it? maybe, but probably not. Did you make it softer, yes. ![]() The blue with the torch would be localized tempering. Blue brings the hardness down a good bit. If you don’t want to reduce the hardness as much you can bring it to a straw color. I do recommend the oven for tempering just because the longer time allows the steel to be more stable, and gives you more even results.

The blue with the torch would be localized tempering. Blue brings the hardness down a good bit. If you don’t want to reduce the hardness as much you can bring it to a straw color. I do recommend the oven for tempering just because the longer time allows the steel to be more stable, and gives you more even results.