So I finally got some help in the shop and started having an issue while I am cutting on the CF Pro AND he is welding. When he starts an arc while I am in a cut, the lead screws jump around. I don’t think it lost any steps, but the cut was choppy. I am thinking if might be the high frequency, has anyone else experienced this and is there a simple fix besides not welding while cutting? We are on separate breakers and the welder is a Dynasty 400. I did not experiment with DC welding or with HF off yet, might try that tomorrow. We are doing aluminum AC with HF on. The plasma cutter doesn’t miss a beat, just the motion controller. Any help would be much appreciated!

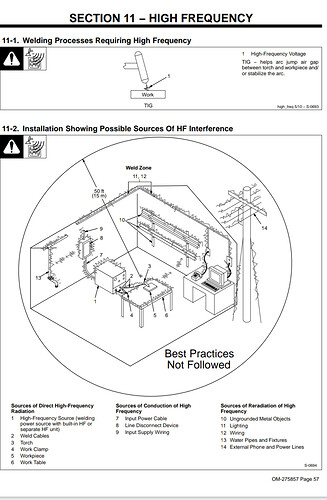

High frequency aluminum TIG is definitely going to put a lot of electromagnetic interference out there.

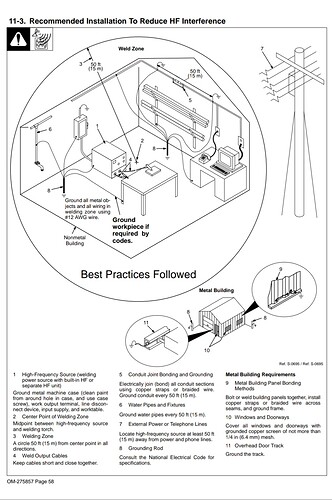

Isolation and grounding rods will help your situation but you’re going to run the risk of interference.

@Bigdaddy2166 has a nice little document on grounding he might be so kind to post.

Also if you look at the higher end plasma manuals for the 200 amp plus range plasma torches they usually have comprehensive grounding instructions in those manuals that you could glean from.

And I’m certain if you look on the back of your Miller there will be a grounding point for a grounding rod on that machine.

Sure enough I pulled up your manual for your TIG welder.

https://www.millerwelds.com/files/owners-manuals/O275857A_MIL.pdf

There’s two pages in the manual that cover mitigating the electro magnetic interference created by your machine.

Pg 57 Pg 58

I have a dynasty 200dx at the shop but I can’t run both machines at the same time so I’ve never suffered any issues.

This is an awsome community! Thank you both for the quick reply and great info. I do vaguely remember reading that in the manual a few years ago, appreciate the reminder! I’ll try some grounding with the welder, panel, and CFPro components. If it’s not an easy fix we will just work intermittently for now until I find a new, more permanent shop. (Whole nother problem…)

Thinking about it my last shop was a metal building and wired very professionally. I didn’t have this problem.

Will let ya know how it goes. Stay Well!!!

Remember not to use the electrical service rod as your chassis gound. Drive in a totally separate ground rod for your equipment.

Actually I now have a ground rod for the pool…house electrical service…and one for special grounding in the shop as I have a 100amp pony panel…

Toolboy make sure your table has a separate ground rod. If you use the pony panel ground rod you can have a ground loop through your equipment. Not always but you can try it first.

The positive DC work cable needs to be connected to it.

Everlast plasma cutters have a ground bolt on rear also needs to be tied into rod. If you dont AC tig weld while cutting you probably don’t need it at all.

TIG and Plasma cut…come on I am a true man…I can only do one thing at a time!!!

Thank you again for the great replies! Next shop I’ll set up the right way as I’m finding help more often and it would be nice to do both things at once. For now it is too much effort We will just have to work around each other when using the table.

Toolboy- I would love to see someone tig and cut as well, the nice think about the crossfire machine is you can hit print and walk away, even to weld. ![]() A few times out of a few all works out as it’s supposed to!

A few times out of a few all works out as it’s supposed to!

Hitting print or go and walking away is like building a fire in the middle of the forest and leaving.