Im not 100 percent sure but im assuming you built your machine right? +/- .005 over 3” should be doable. Thats like inconceivable that it wouldnt be. You may need to go back through and recheck everything, if your travel adjustment was out its possible something else is out as well. My harbor freight mini mill holds that tolerance. I know because ive milled out 80% ar15 lowers on it.

Good grief, what a ridiculous part. How did you get that gorgeous radius? Ball nose? Or did you flip the part and go full depth? The surface finish on the ramp isn’t looking so hot.

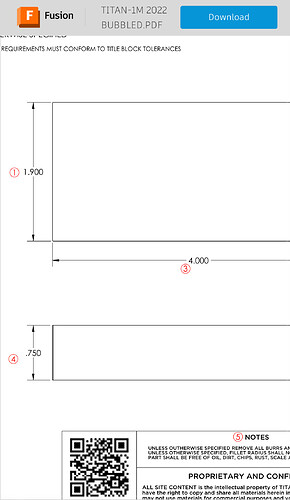

The MR1 definitely has the precision, I achieved the following on the Titan 1M part with very little effort. You can see that I struggled a bit on the part flip but X/Y was great.

What amount of stock are you taking on your finish contour pass? I’ve been hitting +/- .002 on most parts, and some more precise jobs holding less than .001” on diameters. Granted you can’t hold tight tolerances while slabbing off material, but coming back and doing a .010” finish and a spring pass on tight tolerances has given good results for me.

If the programming aspect is good, then I would start verifying tool diameters, tool runout, machine backlash etc.