I’m not sure what’s going wrong. Any time the machine moves in the machine moves to a new cut in the y direction it doesn’t move consistently. Or anytime I jog the machine in the y direction any faster than 50ipm it moves what seems to be a random amount.

Loose motor coupler, or jammed. If the tone of the motors doesn’t changed in their loose if it does then they’re jammed

I’ve tightened the couplers as tight as I can get them, and it moves smoothly and doesn’t change sound and the issue still remains.

Take a video of them while jogging the y axis, or watch them as you do it and you’ll probably see them spin.

Only when this has been visually confirmed or eliminated should you move on to other potential causes.

take a marker and place a mark inside the couple on the motor shaft…

then move your torch around…

then look at the marker…if the mark has moved…then your answer is the couplers…

Yeah that’s much easier. Lol. Unless it slips the exact amount to go back to the mark, but that would be nearly inconceivable.

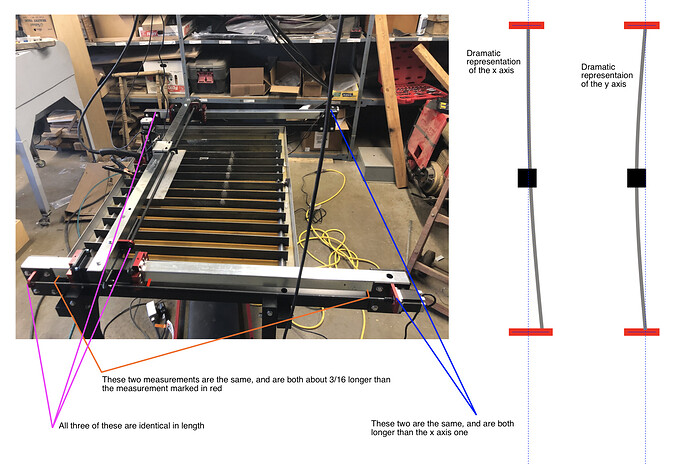

I think I found the issue. The red anodized aluminum blocks that hold the steppers and the end of the lead screw are too long. Warping my lead screw by a 1/4 of an inch. I think I’m going to have to make some irate phone calls.

You may have put them in the wrong spot. Check that first. It’s happened before.

And send pics so we can help you.

Send this picture to the support email at langmuir…they will oook at thias and determine if your blocks are the wrong place…or the wrong sizes and ship you new ones if needed.

The lead screw mounts may be the same overall length but I believe the one for the x is different. I mixed mine up on my install and had to swap them.

If Langmuir messed up and gave you three identical lead screw mounts, then only 1 of the three lead screws would be messed up.

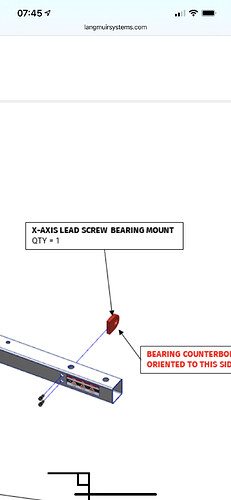

Is the counterbore oriented correctly? If it’s the wrong way, it would not leave enough length for your lead screw and it would bow. I think that’s what I did wrong on mine.

![]() I did the exact same thing. I think the instructions mentioned it but not so obviously that I didn’t use the wrong one. It was only by laying them all out together that I saw one was different. It could use a little sticker that would let you know you’ve got the X vs Y mount.

I did the exact same thing. I think the instructions mentioned it but not so obviously that I didn’t use the wrong one. It was only by laying them all out together that I saw one was different. It could use a little sticker that would let you know you’ve got the X vs Y mount.

I did exactly the same thing also. Its easy to over look if your used to reading instructions when you have parts left over when you think your done.

I’ve fixed my y axis troubles. It now runs smoothly at 300ipm. I loosened all the mountings and then retightened them. That clear up a lot of the issue. Then I lubed it up with some way oil instead of the graphite lubricant I was using before. I’m currently waiting on a new x axis bearing mount to arrive. But this at least let’s me use 80% of my table instead of not being able to use it. Thank you for all you suggestions and help.

Hey TSRat

I am having the same problem as you have described and since I am not that familiar which bolts you readjusted I was wondering if you could send some pictures of what you adjusted

Thanks

Jason