Oh one more thing, how does the torch fire off the table?

So something I noticed and not sure if it has any effect but when cutting the 2t light on the plasma flashes instead of just staying green. Is it suppose to flash? When I cut manually it doesn’t flash.

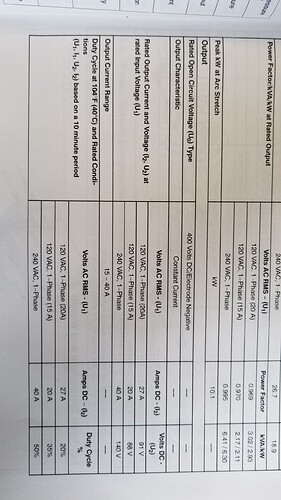

Hey guys, please check the duty cycles of your machine with the amps you are running. My Miller 625 has a 50% duty cycle at 40amps (220) but only 20% at 27 amps (110).

The machine’s duty cycle rating states how long the machine can operate continuously at peak current before requiring time to cool down, given as a percentage of a 10-minute cycle. For example, a machine with a 30% duty rating can operate continuously at peak current for 3 minutes in a 10-minute cycle before needing to cool down…

After you pass your cycle time the cuts get bad and your tips pay the price also.

Remember it’s based on a 10 minute cycle, so if you have a 30% duty cycle at a certain amperage, it cools for 7 to complete the 10 minute cycle. I’ve had to cut many of my pieces into seperate cut paths.

This reminds me of a question I forgot to ask and wanted to know. is there a way to display elapsed time in fusion360 while Your simulating the cut? I was trying to diagnose a cut problem and looked for it breifly but didnt see anything seems it would be good for this sort of thing too

Seems when you simulate a project. One of the tabs has cut time. I may be thinking of something else but check that out.

Yup cut time is there but its total. I wanted to see how much time it was between points in a program. Seems like a read out would be possible to note start and stop times. Like say your having a line not completely cut did it happen 5 minutes into the program? Was it 10 seconds after the last pierce? Would be easy to figure out and since the machines all work.on timers it might help in diagnosing issues. The playback speed is variable but without a reference you.cant even time it with a stopwatch

You bring up a great point, may be what my troubles have been, maybe.

On the 625 ex running on 240 , set to 35 amps what would our duty cycle be?

Would it be the same as if we were plugged into 110 volts or is it higher because we are running 240?

Guess I am confused on how all this works.

I guess I always assumed it would shut down when we hit the peak of the duty cycle like a welder does.

Looks like the MDI tab on mach has elapsed time but never tried using that screen. I guess program tab does also. But that dont help in design just when it messes up cutting

Patriotfab

You show that you are cutting 14 gauge at 100ipm? I can’t cut that fast and I use the same plasma cutter you are using. I cut 14 at 65ipm and they are nice and smooth.

Could that be the issue with your bad cuts?

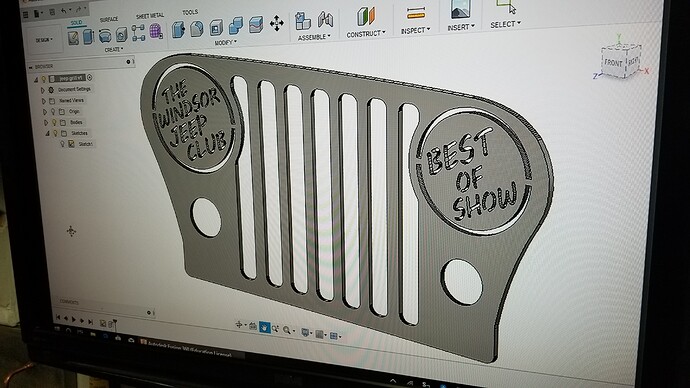

I’m still grasping the concept myself but I noticed the same issues cutting for certain projects. The last two I created about 5 cut paths and what a difference it made! (this project was 23" wide by 14 inches high.) cutting 1/8 mild steel at 100 ipm with little dross.

Did each headlight seperate, 4 of the slots, then 3 slots and the 2 turn signals, then the date and outside perimeter. 4 cut cycles. Zero distortion. If I ran it as one cut by the end I would have jagged beveled edges and areas that did not cut through.

Very nice Todd,

I’d like to copy it for our San Diego Jeep Club, can you post the DXF file?

Bob

This was a 3 hour creation. I’ll post it as soon as I stop getting “something went wrong with our server” errors. Or I can customize it for you and send the the sized file from 360 to your email for $20. toddkelch@gmail.com