Hi guys, I have the Crossfire Pro, and I keep getting the ihc error code. It says to check for slack in my torch cable, which I have. Is the IHC system just so sensitive that any movement gives it an error? When It happens, I just jiggle the torch holder a little and I can then continue the cut, but it’s really irritating when I have to do it on 80% of the cuts. Will a machine torch help? If so, what is a good one to try? Thanks. You guys have helped me tremendously just by reading through the topics on this forum.

Can you check that the two wires connected to the lead nut and the brass contactor are secure? If you are getting an IHS error randomly just jogging around it could be a loose wire.

What motion control firmware are you on? V1.1 or V1.2? It will indicate the version at the top right of FireControl when plugged into the machine.

Also clean you z axis eccentric bearings and rails. Mine were all goobered up and causing it to bind.

I’m using version 1.2. I’ve check the wires, and if there is a loose one, I have no way of tightening is because of where it is. It’s gotten to the point where I can’t finish a project because of this error. I checked out the IHC troubleshoot guide, and nothing helps. I’m waiting on an email from Langmuir, but who knows when that will come… Sorry, I’m just very frustrated. I spent a lot of money on this machine, and right now, it would make a good boat anchor…

Turns out I had the wrong Post software! The issue has been resolved. Thank you to whoever helped me out via email from Langmuir.

i’m having the same issues and running v21.13

I get half cut circles, missing line cuts, but maining have never had voltage for IH work correctly

Im having the same problem but it happens right at the beginning for me. I hit start and the machine goes to start position and then throws this fault, it neber tries to fire or anything

What machine do you have and does it have a powered Z axis?

Generally, this error is caused when you try to run G code for a machine with a powered Z axis on a machine with no Z axis. It can also be caused by a disconnected or broken wire on the IHS system, on a machine with a powered Z axis.

The “expected state” for the IHS is a closed circuit and machines without a Z axis do not have an IHS switch to close the circuit. The circuit is always open on those machines.

If you don’t have a Z axis, your pierce and cut height values in CAM must be set to zero. If those values are not zero, the post processor adds the IHS commands to probe the torch down and set the Z zero.

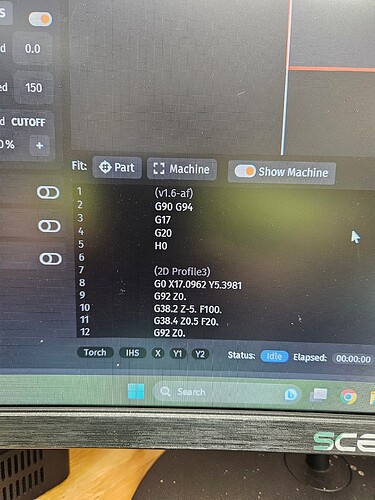

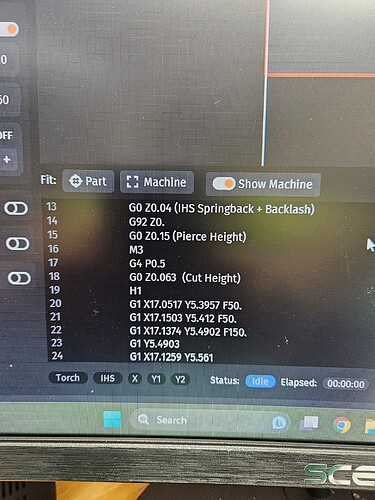

If you can upload the cut file here, we can tell you what the problem is.

I have the crossfire pro with Z axis. I’ll have to wait until i get off from work to upload the g code

You may not be able to upload anything until you make a few more posts.

Since you do have the IHS system, there must be a break or disconnected wire in the IHS wiring.

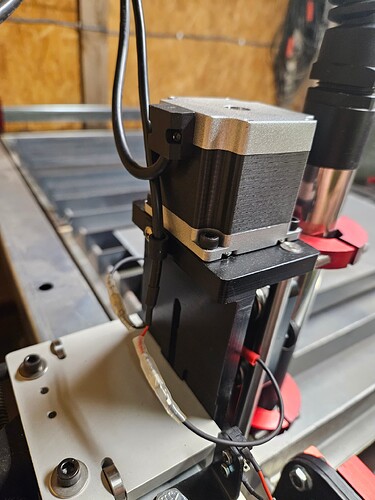

Check the wires that plug into each side of the Z axis and make sure they are fully pushed into the connectors.

Make sure the IHS cable is connected to the control box.

Look behind the Z axis carriage and make sure that the IHS switch isn’t being held open by the lead screw.

The code looks fine. It’s hard to tell from the picture, but those connectors might not be fully pushed together. Also, check the ends of the wires that are screwed to the switch. Make sure they are tight.

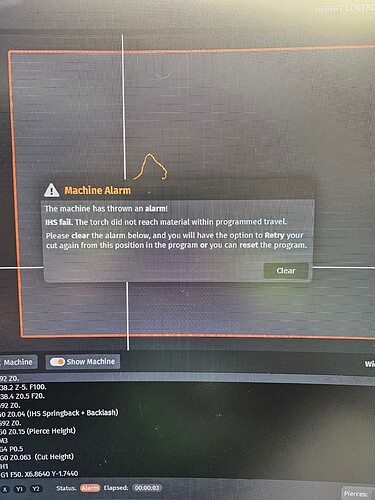

Take a pic of the error message on the screen.

What is your plunge rate set at? Is the coupling in the z motor tight?

OK, that is a different issue than the IHS Fail error. The IHS system is programmed to probe downward, up to 5 inches, or until the switch opens. If the Z axis thinks that it has moved at least 5 inches and the switch has not been opened, there is likely a problem with lost motion on the Z axis.

As Phillip suggested, you should check the coupler between the Z motor and the lead screw to make sure it is tight. There have been many reports of new machines with a loose coupler that allows the motor to spin without moving the lead screw.

Turns out the barrel clamp that connects the wrom gear of the x axis to the stepper motor was lose on the motor side amd thats what was causing my fault. Thanks everyone for taking time to lend ideas and possible causes