As the title suggests, I’ve been plagued by bevel issues with my setup. The convention is the right side of the cut relative to the forward direction of the torch is the “good” aka less beveled side. For some reason, my experience is not the case.

I know my consumables stack is assembled correctly with the correct consumables. I cut clockwise outside and counterclockwise inside, as is convention, and get an almost perfect cut on the left of the torch and a pretty heavy bevel of the right. Opposite convention. I am specifically leaving out torch to workpiece squareness because my bevel is consistent through all cuts. Not limited to one direction or side. It almost seems like my torch swirls the wrong direction.

Anyone have suggestions? I am not opposed to flipping the cutting direction, but can’t seem to get fusion360 to simply reverse the cut direction without having to change compensation, which then has to be almost tripled because it thinks I’m cutting inside when cutting outside, etc.

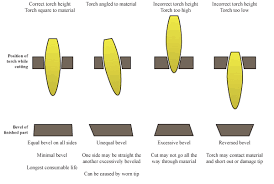

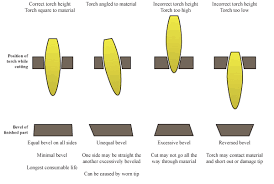

Here is an excellent example of bevels and their causes. Now, I downloaded this from the Plasma Spider forum.

1 Like

While helpful in diagnosing cut height issues, that is not my problem. I have an issue where the “bad” bevel is on the wrong side of the travel path. If the issue was a physical alignment issue it wouldn’t give me an identical result to the left and right of the travel vector at all times.

Are you using a hand or machine torch? How is the torch mounted? Is the bevel on the X or Y cut direction? Pictures would also help.

1 Like

Genuine T45m torch, bevel occurs in all directions, it’s opposite the conventional side. Doing an inside cut (hole) the bevel is on the non scrap side as the torch moves counterclockwise around the hole. Opposite side is the “good” side for outside cuts with the torch moving clockwise. Or if the torch is moving to your right, when looking at the torch as it moves away, the left side is the “good” side. I’ll see if I can get pictures later.

I’m wondering if my electrodes aren’t genuine despite them coming in hyptherm packaging and the swirl on them is reversed causing the plasma to spin opposite

Yes consumables mostly cutting tips can cause a bevel, but most of the time it will be consistent. There are a lot of copy consumables out there. The package should say Genuine Hypertherm anything else they are copy’s. If your getting them online from a Hypertherm dealer or at your local weld shop they may be copy’s.

As far as the bevel, did you squire the torch with the table? If you lightly hold the top of the torch and wiggle it does it stay in the same place? I tape a marker to the torch and wiggle it over a piece of paper this will tell you if something is lose.

3 Likes

Torch is square to the table and workpiece. I don’t get any movement in the torch other then tilting back when I put a lot of force on it. The lead moves freely with the head and doesn’t appear to impede movement. I don’t really understand why the “good” and “bad” sides are reversed for me, never noticed before but looked at some of the stuff that I’ve cut in the past and had the same issue.

I have found that I have to run significantly slower feedrates, to the tune of half, than the book value to not get a large bevel, kerf matches the book +/- 0.010", cut height is per book, voltage per book. I think I’ve seen issues like this before on here and it pointed to people’s air supply being dirty or now enough flow. I have a 2 stage compressor making 16.2 CFM. The air goes through a 5um filter, then through a refrigerated dryer w/ coalescing filter, then out to the plasma. More than enough clean dry air getting to it. LEDs on the front never drop.

I compared the new consumables to the old stuff I had gotten from Hypertherm HQ and they appear identical, definitely got genuine consumables. I ran some aftermarket stuff and it was inconsistent.

I think you have something lose or binding and causing the bevel. Most people can not tell the difference between the copy’s and original consumables. A picture of how your torch is mounted may help.

4 Likes

@mechanic416 You were 100% correct with the binding. My torch was being pulled ever so slightly, it didn’t have enough slack from the boom to the torch. Bevel gone, successfully cut a bunch of stainless and 1/8 and 1/4 mild steel without issue.

Thank you to everyone that helped

6 Likes