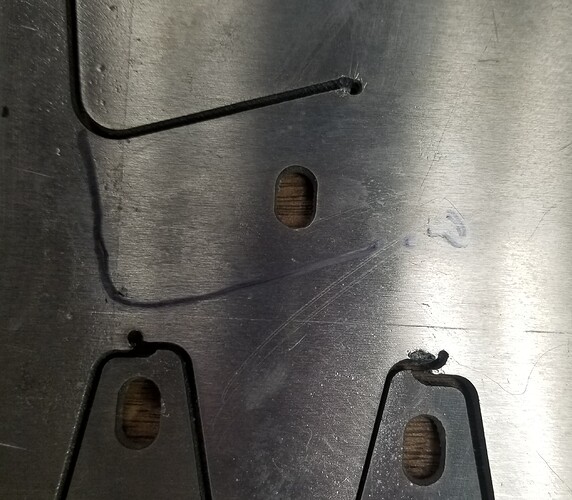

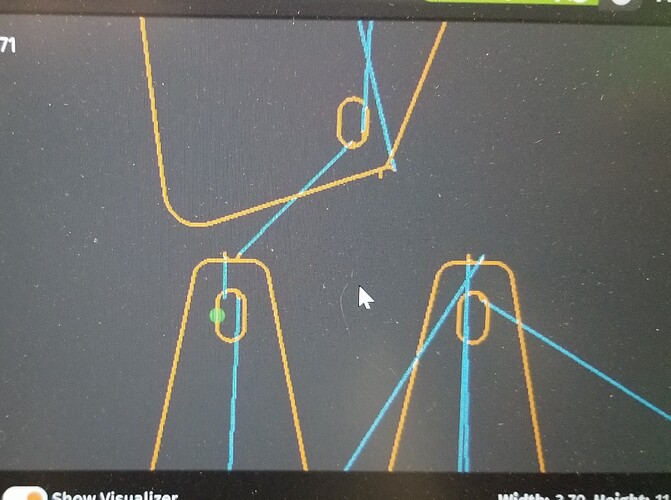

Help ran a few programs and the positions of everything keep moving. The start and end positions never line up. The last one I ran it made the hole in the right spot and started going around the perimeter almost a inch from where it was supposed to, i literally have the plate clamped to the table so it can move. need help material is extremely expensive can’t keep wasting it.

Check your lead screw couplings they work loose from time to time

if your drawing shows it all nice…then it cuts out of alignment…then it will be your couplers are loose…just as some crazy Madman said…

Lead screw coupler loose or stripped out. https://www.amazon.com/dp/B002SJSUGC/ref=cm_sw_r_cp_apa_glt_fabc_PY2HCRNH8DDVYRATC4HQ?_encoding=UTF8&psc=1

These will solve the problem once and for all.

Crazy me,. Ok maybe just a little

Lead screw couplers are tight. Very tight. As tight as they can possibly be. I am well above average mechanically inclined, I have made and assembled parts that are on satellites orbiting the earth right now. I know when a couple is slipping and I can say the problem is not in the lead screw couplers.

Machine is basically brand new and the problem is always on the y axis.

Wow. I’m impressed. Too bad you have these problems with a relatively simple mechanical system. Huh, must be magic.

As you are well above the average mechanically inclined then why are you asking for help?..we are obviously not to your standards of mechanical knowledge…can you please tell up what the problem is…

Only other thing it could be is a loose or not seated properly DSUB connector. But with your technical prowess I highly doubt there is anything wrong with the assembly. I bet you’re a hoot at dinner parties.

Thanks for all the help. Good group of helpful people here. Like I said I’m mechanically inclined. Not electricity or electronically. And am wondering if the problem is in there.

It’s not the stepper motor couplers they are drilled and pinned through the stepper shaft and lead screw shaft.

I’m not cutting on the axis limits I’ve tried it dead center of the table with the same results.

Its not the work piece moving, I’ve clapped the work piece to the frame.

Steel is at a all time high and I’m getting tired of scraping it.

For test cuts and such I use washing machine & dryer side panels. Our town landfill lets folks take them. They’re usually pretty easy to pop off - they just use slots and fingers with a few qtr inch head sheet metal screws. Can usually strip a washer in under 5 minutes with a battery powered impact driver ![]() Just put it finish side down and grind off a bit of the finish so the work clamp makes good contact on both sides.

Just put it finish side down and grind off a bit of the finish so the work clamp makes good contact on both sides.

Nice big flat sheets of free (or really cheap if your town charges you for it) steel for working out designs or new projects.

thanks for the tip, if I ever get this thing to work. ill have to take a impact with me on garbage day, around here you can just leave appliances on the side of the road for pickup.