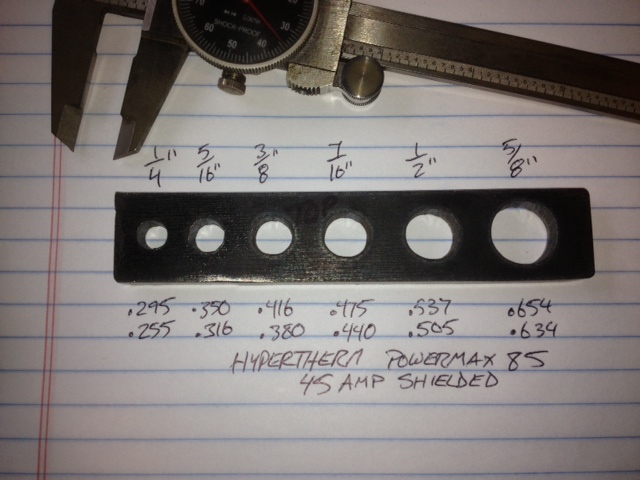

Plasma cutting good quality holes requires a height control and a good quality plasma system. If you are piercing at the plasma cutters suggested cut height…then expect the nozzle (some call it a tip) to be damaged as soon as the very first pierce. The nozzle orifice shapes the cutting arc into a spinning, rotating column of hot, ionized gas (as much as 25,000 F with an air plasma). The arc relies on the accurately machined copper nozzle orifice to control its shape, however when a crater or a nick is formed (from piercing too close to the material, blown back molten steel will damage the copper nozzle) the ionized gas arc changes shape and affects cut edge angularity. To get thousands of starts out of a plasma torch nozzle you must pierce at the recommend pierce height, staying in that location with no x, y or z movement, then rapidly index down to the recommended cut height, then start the x and y motion. The correct pierce height directs molten metal away from the nozzle orifice preserving iuts ability to keep the arc straight. Indexing to the correct cut height after the pierce gets the “sweet spot” of the plasma arc properly positioned in the materials to produce the best quality holes. Air plasma holes will always have some taper, however they can be round on top and bottom when pierce height and cut height are maintained as the plasma system manufacturer suggests. (I worked for Hypertherm for 41 years…just to reference my experience here!). Here is a pic of various holes cut with proper height technique with a Powermax system operated at 45 amps, shielded mechanized consumables on my home shop machine. To allow a 1/4" bolt to drop through a plasma cut hole, you must size the bottom of the hole (increase the top diameter accordingly) This is 1/4" steel. Top numbers are the desired hole diameters, bottom numbers are the measured top and bottom diamaters.

5 Likes