So FireControl is not freezing? If you toggle off THC in FireControl will it cut your whole program?

It definitely sounds like an interference issue. Move your plasma cutter as far away as possible. Make sure you have plenty of ferrite chokes installed. Make sure that you have no ground prong on your laptop power supply. Make sure you have no continuity between USB and the table.

I’ll try all that. Thank you.

Is FireControl freezing or are you losing arc? If you actually see an arc voltage lost error, then firecontrol isnt freezing. A video would be extremely helpful.

https://photos.google.com/photo/AF1QipPFMHJAhcGaJyWdGgV2HJjM6Qth_Q7muFX7g2kl

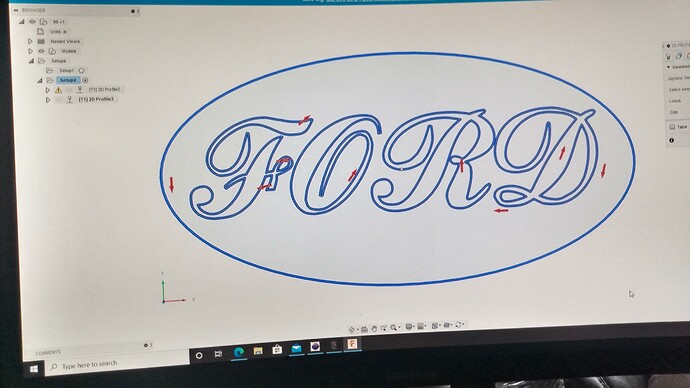

It failed on the first try so i started it over just next to the first. Notice on the screen how the lines disappear as it cuts. I dont know if its supposed to do that or not. And you cant see it in the video but the gantry is kind of jitery. I checked all the bearings and they are ok. It moves fines when manually jogging it. It drops out still with arc voltage loss almost every time.Could it be a faulty relay?

It appears that there is an issue with the link you posted.

that didn’t work either. might have to do it in YouTube.

check email

This program looks like its very unoptimized. The torch is slow and jagged through most of these loops and never really getting up to speed (by default THC disables at 85% of the Program Speed in the THC module). The large number of nodes in the program over a small distance will mean that the torch dwells too long in places and it will eventually lose the arc.

Are you posting with Fusion 360? You will want to try ‘smoothing’ your toolpath to decrease the number of individual lines. Heres a video from NYCNC that explains it (albeit in the milling sense)

It cut 10 of those Ford plates when i first started up ,perfect.

Does the same thing with THC turned off.

The issue with 100% certainty is what @langmuirsystems said. There are simply too many lines of code to parse through so the torch never builds enough speed to prevent the arc from extinguishing. It is also the reason why your machine is running so notchy.

You need to employ smoothing in your CAM to reduce the number of G code lines. That will enable the torch to get up to speed and the arc to stay on. Your machine is running as it should.

Muting this thread that really should be handled by support email…

Like I said it cut ten of them when I first started up perfect,smooth no stops no nothing but smooth cutting.

So its not the g-code lines.The first ten it cut at 150in./min no problem.

I know it’s late but when’s the last time you have drained the water from your compressor, im not certain but I believe I saw some water shoot out of your torch. To definitely want an air dryer and make sure to drain the water from your compressor.