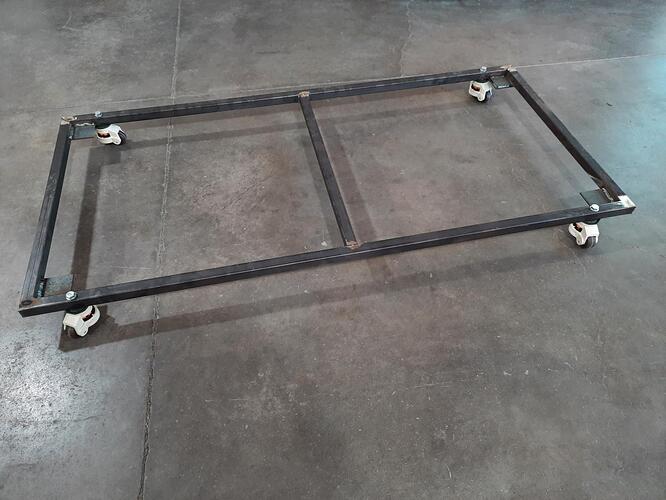

Whipped up a rack with castors this afternoon. Used 1.25" square tubing, self-leveling casters (https://smile.amazon.com/gp/product/B07ZD1T5NW), a little flat stock and mig welder. It rolls great around the shop. I’m tacking in a sheet metal shelf for the Cut 45, bucket head wet vac and other stuff. 3 hour build, should have done this sooner.

Are you a giant? If not, how much did you cut down the legs? I’m cutting at high speed a lot lately and thinking of shortening the legs to stiffen the table…

Caption: “Honey, I shrank the Crossfire.”

Giant, now that’s funny. Stock Pro, no mods. I’m 6’3" on a good day, like today. Got to spend the afternoon in the shop.

I guess I need sleep! Thanks for the quick response.

I like the idea…and 6’-3"…just short of giant …hahahaha

I have been planning this exact same build since I got my crossfire as well - ended up using the castors on my mill instead and now have to order more to weld up the frame for the rack to sit in. I was thinking of using angle iron vs tube - but this looks pretty rigid!

I thought about using angle but opted for square tubing because I had it. Angle would have been fine also. Good luck, its so much nicer to roll around.

Stupid question: (I think the answer is yes) Did you take the levelers off the table legs? and did you attach the table to the rack in any way? (pass through bolt/weld etc)

Oh sorry for delay, yes I removed the original leveling feet. Turns out their diameter is bigger that the leg square tubing used. With the feet on, it won’t fit on my platform.