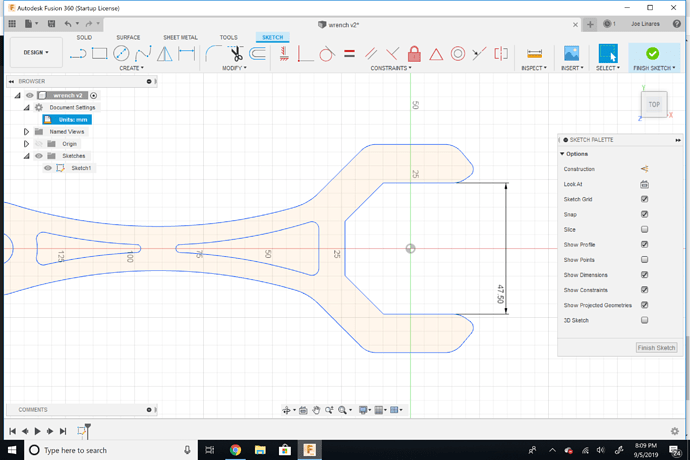

I wanted a wrench to adjust the casters on my CrossFire table. And it seemed like a good part to start with, as it was fairly simple to design and cut. I did oversize the octagon slightly, as I was not sure how it might cut. I could have probably designed it to size.

LOL! When I was adjusting my table again last month I thought about this as I used a channel-lock to do the trick. Thought a nice Crossfire specific wrench would be good but I was too lazy ![]()

Pretty Cool…

Thanks

Before making the wrench, I just adjusted the casters with my hands.

Next project will be a laptop stand, still tossing around ideas on how I want to design and build one.

What size are the caster nuts? I love this idea but I’m not in front of my machine to check size.

Mike did you share the file for the wrench? I wouldn’t mind making one myself. Thanks

I made one myself. If Mike doesn’t want to share his file I can upload mine for anyone who wants to use it. I didn’t skeletize it quite the same as he did (I used my name cutouts) so I’ll modify it first though.

I’ll upload mine tonight after work. Though I would encourage you to design your own if you are new to cad/cam as its a simple part to start with.

I uploaded my wrench design

http://www.langmuirsystems.com/fireshare/47mm-crossfire-caster-wrench

Thanks Mike, you’re right I think it would be an easy design to make. Just so many things I want to make. I’m proficient in CorelDraw and I’m learning Fusion 360. Fusion is quite powerful and I’ve already used it to design a couple of 3D printer item. Thanks again.

Fair enough, I am pretty quick with Fusion 360 and Solidworks. I have yet to try Coreldraw, but I used to use Illustrator at work. I am on the fence on if I want to pay $20 a month for Illustrator, currently my Crossfire is just for my own personal use. Its not creating income, which makes it hard to justify a program like Illustrator or Coreldraw for the occasional hobby projects.

I have Inkscape, I struggle with that program.

what size/gauge material was used to make the wrench?

I made one similar to this one in 1/8". They don’t have to be huge - you’re not torquing it down monkey tight.

11 gauge, 1/8 cold rolled steel is what I used. I wouldn’t go thicker than 3/16, to thick and it might not fit.

is the opening supposed to be exactly 47mm or 47.5mm? when i added dimensions between the inner top and bottom opening in fusion, it came out to 47.5mm

I made it slightly over sized. Having a little slop on that sized wrench will make it easier to use. And a tight fit is not needed in this application.

ok cool, thanks!! gonna be my first “trial” cut with the table and cutter.

I haven’t played with fusion enough to make a modification yet. And really…I freaking HATE stem casters. So I’m gonna weld some plates on the bottom and also add leveling feet to the crossfire frame. That said, I think a great modification to this design would be to add a square hole to fit the water table plug. Not sure if this was intended, but the end of the small cutout actually fits the water table plug… sort of… that’s what gave me the idea.

Thanks for this it made a good first cut for me.