Is not clamped at the bottom. It was working fine, I was cutting a piece then it start misfiring and suddenly it stop working. the pressure is fine.

Did you check the electrode? Make sure you can push it up and it snaps down. Could be stuck. Sometimes debris gets it hung up. Torch won’t fire if its stuck.

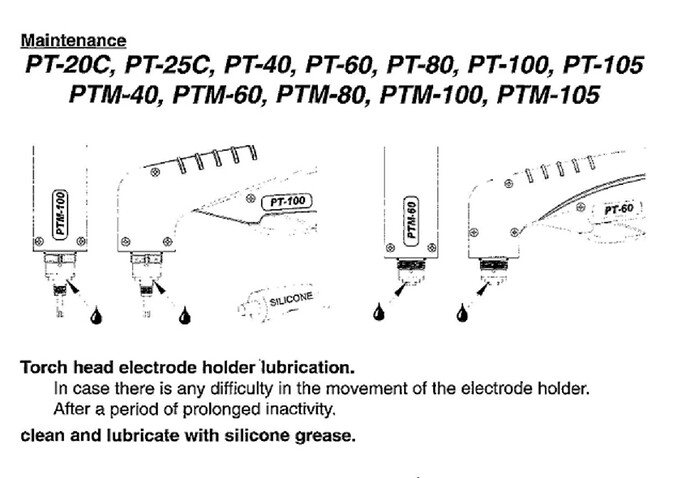

First thing you do when this happens is turn off your plasma cutter and replace the cutting tip and electrode. When changing the electrode make sure it is moving freely in and out. If its sticking or jamming up you need to clean the plunger by working the electrode in and out and using air to clean it. You can also remove the electrode and use the air test to help clean it out. Never use any types of spray cleaner as it can mess up the orings in the torch head. Only use silicone grease on the plunger and work in in and out till it frees up and you should be fine .

How do you know air pressure is fine? could have restriction in torch head or low pressure to torch, did you check torch air supply with gauge?

one of the big issues with Everlast torch heads is people not running enough post flow…the 62i has adjustable post flow…it should run at least 30 seconds after a cut…always…

next…the little safety pins that touch the retainer cup…it they get dirty the stick very easily…clean them…make sure they spring back nicely…

I had an interesting problem with my everlast 52i with machine torch yesterday. After about 10 minutes of successful cutting thc randomly raised the torch head while cutting up to about an inch. Something else that would occur is the the cut would fail to fully penetrate the metal. 16 gauge at 28amps and 123ipm. I changed consumables and had the same problem occur. I blew out the torch head with compressed air and all of the z carriage. I then noticed that it would fire at 23 amps and never transition to the cut amperage. That told me I think that I had a bad connection to the work clamp. Previously I had repositioned this as an initial trouble shooting step. Wire wheeled clamp. Same issue. Ultimately what fixed my issue I think or the last thing I did before it started working right was increase my pierce time by 10percent. My theory was for whatever reason the torch was moving before full pierce was made and the movement too soon without a good start point for the cut being established was causing thc to hunt. Does not explain why torch wasn’t transitioning from start amp to cut amps. However with that increased pierce time the day finished properly. Of added note it was 35 degrees in my shop and water table was mostly frozen. I bought a new work clamp with copper teeth instead of steel which the machine came with and will change that out today.

temp can affect a lot of things…

if your shop was that cold and your computer and plasma were warming up you might have had condensation issues inside the boxes possibly causing electronic issues…

then not to mention what cold does to bearings and other moving parts…slowing them down…

heat from cutting then cold…then heat from cutting…then cold…