Okay here are the .dxf/.stl files.torch float.dxf (189.9 KB)

motor spacer block.dxf (144.4 KB)

Fixed.dxf (338.0 KB)

floating carriage.dxf (301.5 KB)

Torch Holder.dxf (896.2 KB)

Cool. Just need to make them stl extensions & they’re ready to go.

If you need help with the electronics just ask. The write up I did probably would answer 95% of your questions.

Do you find the weight to be a concern when it’s at the distal end of the arm?

I was going to add a linear rail to the far end

I didn’t find it an issue in my setup. I did have to re-level my x axis gantry as there was some deflection but that was expected.

A linear rail parallel to the y axis (I think it would be your x axis now, if I remember correctly) would be nice. I think it would be difficult to get the linear rail and y axis tube not only parallel but coplanar.

Do you happen to have a parts list of what you used such as linear bearings and screws. Already have stepper motor and driver and some limit switches. Thanks

Can anybody download the DXF files, I gust get a error.

Just downloaded all five

once you download you need to change the file extension to stl.

Nice. Have you wired it up & gotten it working with the Crossfire control box?

Any update on the functionality of this? I’m considering building one myself, but would love to know it works before I get started!

Thanks for sharing all of the good work.

Same here, would really like to add this if everything worked out.

Have not had a chance to install it yet

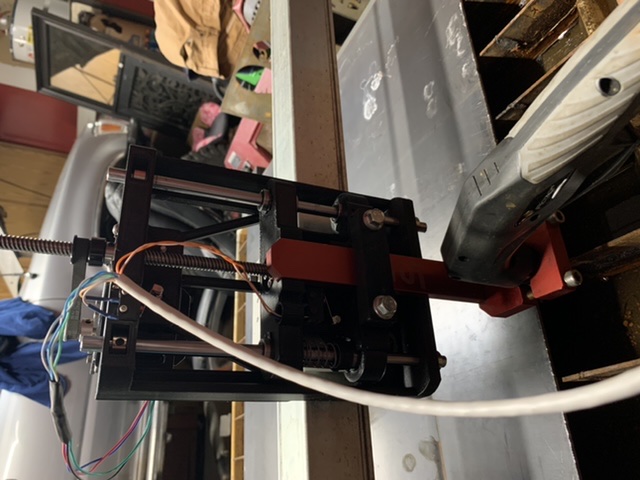

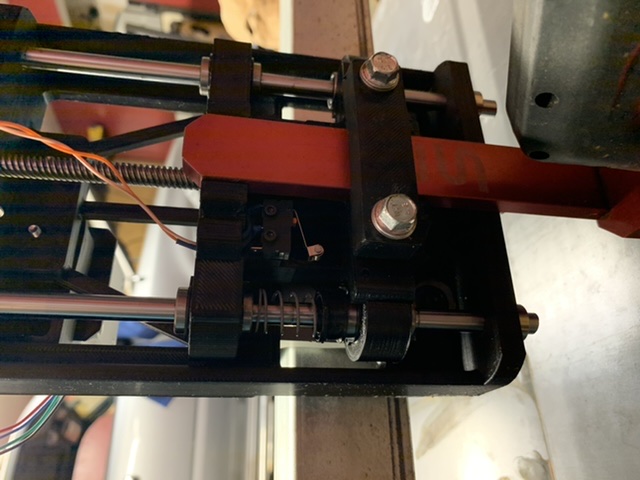

Thank you @Kentucky13 I used your design as a starting point for my z axis, then did a lot of reworking on the size mainly to get it to print on my size bed first.

Then I resized the torch holder slide and a couple other things.

But got it all wired up and working tonight, with some help from @Burgs04 write up.

Any updates on this project???

You liking this z axis so far? Would be great to see an update especially if there were any wear issues.

@TeasleyFamilyCrawler, Have you used the same filament as suggested above? How long have you been running and what results are you getting?

This is what forums should be about!

I used abs to print my axis and it work good.

I Cut two full sheets 2ftx2ft of metal and it was working good. When I redesigned it to make it fit my printer I think I had a little play/ not as sturdy structure to support the torch mount. I did take a lot of material away from the torch holder and also the slides so it even used shorter linear bearings. But I have gone back and did a little more work on my design to ad more structure and the longer bearings again, but before I reprinted it I sold the table.

The only design issue I had with the original design for my table was the clearance for bearings and the bolts on the mount to the gantry it was just alittle off but I just adjust it for my redesign/table.

If I end up getting another table I would print another because it worked good, and didn’t ad that much weight.

The only caution I would tell people before doing a setup like this or any z axis setup, make sure you understand/ or at least have any idea how to setup Mach3 to control the z axis before buying parts to build the z axis.

Has any one installed a Price CNC THC controller on a CrossFire

and install 6 home /limit switches into one input

The 3 remaining inputs for OK,UP DOWN