@Kwikfab - how does your round hole quality on your new table compare to the crossfire?

It is significantly more consistent from one to the next all across the table compared to either of my last 2 Crossfire tables both in size and roundness.

The only time I start to see a bit of tapering (after having done many) is when my pierce count starts getting up there in the +400 range.

We’ve been seeing triple digit weather most of the summer so I know moisture is kicking my consumables ass.

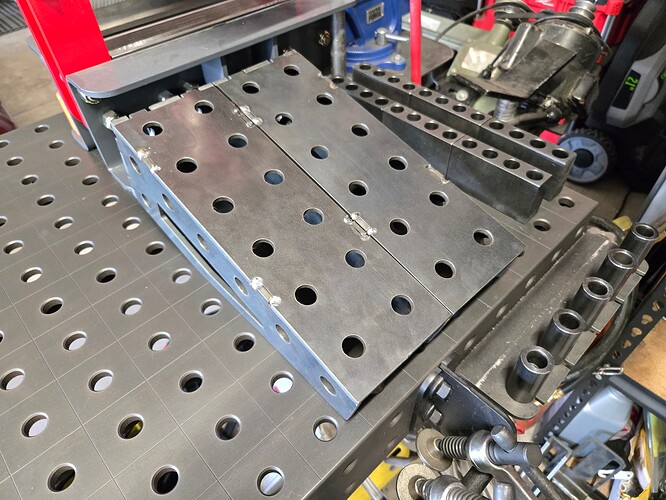

This is a picture of the day I cut those but if you look closely, my table’s built-in CAM allows a lead in to start from the center of any circle.

I never used Sheetcam, but I want to say that could also be adding to the quality of the cuts as well.

Thank you for sharing. I may have to get someone to do a particular hole pattern in sheet Cam and I’ll duplicate it in fusion and we’ll do a side by side