Hey everyone, I’ve been looking for a couple days on this and other forms and so far I’ve found bits and pieces of info but haven’t been able to put together a full solution. I’m a knife maker and cutting out knife blanks is the majority of what I do with my plasma cutter. I normally cut material that’s between .076" and .25" all high carbon and stainless. I cut pinholes in these blanks in 1/8", 3/16", and 1/4". I’ve got these cuts pretty much down. I do a 90 degree lead-in that starts at the center of my smallest hole. I have a 45 amp cutter, I run the feed rate at 30 IPM and work at about 18-25 amps depending on the material.

The problem I’m having is that this low amperage and feed rate makes for very messy edges. I use fusion as my cad and cam. So far I haven’t been able to find a way to have separate post production setting for holes and edges. I’ve read people talking about doing separate layers which I don’t fully grasp. I think I would like to run two separate g codes for each but so far I cant’t get the edges and holes to line up. I feel like there’s an easy fix here but I’m brand new to CNC work and it seems like a mystery to me.

Any info would be appreciated! Thanks

you have come to the right place…maybe me is not the right person…but you will get answers here…

I do not know fusion…but there are many that do just what you are asking.

In fusion 360 these layers you’re talking about are referred to as “operations”

As soon as you click the 2D profile icon it automatically add a new operation.

Or

You may right click on your setup (this is on the list in your left hand side of your screen) and select add operation.

In the 2D profile menu for an existing or new operation you can change the feed rate of every aspect of the cut whether that’s slowing down for holes or speeding up for lead in all those settings are available to you in this menu.

If you post a *.f3d I could make a video of showing you how to set up these different operations.

You may have to comment on a few different posts before they’ll allow you to upload something though considering you’re a new user. By the way welcome to the forum!

Thanks for responding. I should have included that I have done separate operations. My issue now is getting them to line up. If I run all the holes for a set of say 12 knives, then run the profiles I can’t get them to line up. Is there a way to do this in fire control? In other words if I cut all my hole, work zero, open g code for profiles and cut they’re not centered.

When you post your setup both those operations should be included and automatically line up?

Are you posting each operation separately and then reloading it in fire control for each operation? If so don’t.

Go back in , click the setup you want to post then post it and it should post all operations together in one little tidy G-Code package.

Do not post the operations individually.

I see! I was posting individually

So I tried doing this and Fusion said this can only be done with a paid subscription. Does this sound correct?

It very well may be.

I pay for a subscription so not sure what’s not included in the free version.

Pretty good deal right now for a subscription.

350 US dollars for a year or just under a buck a day.

But you could get around that by using " feed rate optimization" to slow down all your holes and just do it with one operation.

I’m out in the field today but when I get back I could post a quick video on how to accomplish that.

Another option would be you could post them individually but you would need to make sure your “stock box point” in your “work coordinate system” which is in your setup tab in manufacturing refer to the same point.

Then when you run your second operation in fire control it should line up perfect.

I have had up to 6 different tool paths /2d cuts under a setup in fusion and have been able to post all to one file without a subscription. My feed rates have always been the same on them only changed leadins to fit tighter areas. So not exactly the same. I will try a different feed rate on one and see if it lets me Tonight

Let me know what you find out. Also could you walk me through your post process? just so I have a better understanding

have you registered your software in Fusion as a small business?

apparently you can do this if you make under 100k a year and get almost all the features…

as I am not a confusion person I am not sure this is still in place…

Same error,. The free version doesn’t support tool changes. If it was me , I would do the following

- create new setup with box point being lower left corner.

- create 2d cut path using the tool setup for interior holes

- create 2d cut path for extior profile using the other tool.

- click on the first 2d cut path and post. Saving with name1cut.

- click on the second 2d cut path and post saving with name2cut.

- load steel set orgin /0,0 on fire control.

- load name1cut and run program.

- after first cuts are made click go to my zero.

- load name2cut and run.

Part should be cut

Not for a couple of years. That’s when I bailed. I’d be surprised if they relented and went back to that licensing model.

This is the application form for start up businesses under $100,000

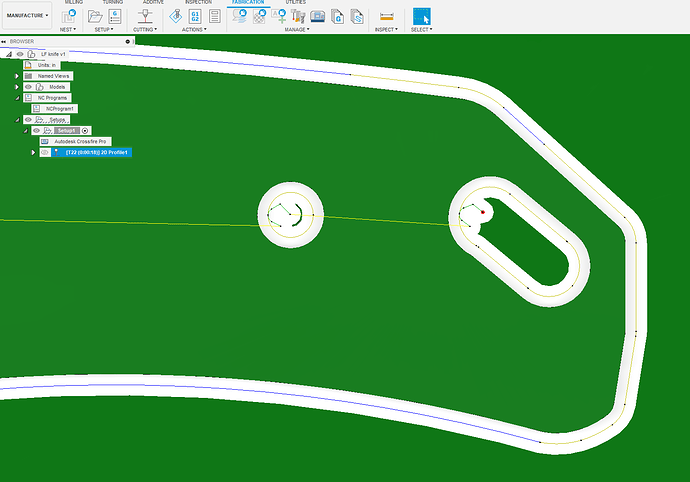

Here is a bit of a walkthrough using “Feed Optimization”

I used this knife from fireshare Hunting knife | FireShare | Langmuir Systems

ended up with one tool path with different cutting speeds

LF knife v2.f3d (115.5 KB)

knife example.nc (4.2 KB)

Hunting knife minus construction lines.dxf (8.9 KB)

In this screenshot you can see that the toolpath is highlighted in different colors.

Red dot Starting location

Green linear line Pierce clearance, lead in , lead out

Green Circular line Lead in radius , Lead out radius

Black Dot Point of change

Darker yellow Reduced feedrate

Bright Yellow Rapid between cuts

Blue Line Cutting feedrate

Green Dot Ending location

should get a mic so I can talk over these videos …

What kind of Plasma torch are you using ? Why run such low amperage ?

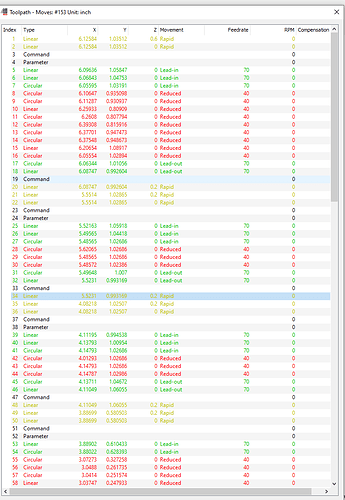

here is a toolpath list show the different cutting feedrates. ( reduced feeds are listed in red here)

Holy crap man, this is exactly what I’m looking for. Yes! Please mic up, that would make this much easier for me to follow. I’m so new to this.

There’s three dots in the bottom right hand corner of the video where you do have the option to slow it down.

Should get a mic, would like to get more serious about making instructional videos for Fusion 360.

Currently have quite a few irons in the fire.

Have you tried it? I know several folks who did but we’re rejected because they weren’t looking to use it in “new and innovative ways”. It seems Autodesk uses this as a way to help edge test the application, not as the general support of startups & home-based hobby businesses that it was oriented towards originally.

It’s worth trying, but I wouldn’t pin my hopes or plans on getting approval. It’s likely that the standard annual license costs will apply - although they do have regular sales like now.

I haven’t tried it. I don’t think I would fit their criteria.

Really I should try to get a educational license but I have not pursued that yet.

At 140 bucks sheetcam is a very good deal.

But not having to export and then import between programs and having a full parametric design with history is worth the dollar a day for me to have a fusion 360 subscription.