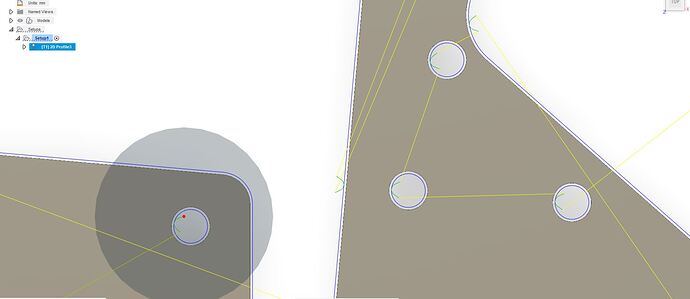

Having issues with random cuts not connecting start to to finish. On several different designs I’ve done. Always different distances apart. Nothing on fusion shows any indication that it should be happening. Anyone have any ideas? Thanks in advance

I believe that the first thing that people will tell you to check is to make sure that your set screws are tight and on the flat side of the motor shaft.

Slipping motor on the shaft would throw the whole piece off, yours looks symmetrical. Because it seems to be stopping the same distances before it should on each mess up, that leads me to think your “lead out” settings are not right…maybe. But yet it does not do it on all of them.

I wonder if those were not closed loops in your drawing. Maybe those lines only looked connected but were not in the file.

I am by no means a expert and one will be by soon with better info.

You can easily save that nice piece by coming through the back side with the hand torch and a straight edge to guide you. It will not be perfect but only you will notice it.

This looks like the lead outs aren’t completing. If you look at your cut paths in fusion it should show where the lead outs go.

I’ll look at that when I get home tonight. What exactly am I looking for and how do I fix it?

Just compare your cut part to whats on the screen. you can see where one of the loops starts and stops then there are green lines on those ends if you have lead-in and lead out set. to me it looks like this is at the end of each cut rather than the beginning but you’ll be able to tell when you compare

Thanks, that’s what I’ve been doing with them. Just frustrating not being able to figure out what I’m doing wrong. It’s happening on other pieces I’ve done as well not just this one, so it’s clearly something I’m not seeing in my design processes

If you could upload a small file that you are having problems with I would be willing to load it on my table and see if I get the same results. Nothing large maybe a small 3x3 piece that is giving you problems.

This is what leads look like in one of my files. the cut paths overlap, the green parts are the leads and the yellow is the rapid between cuts.

Is there a chance your hitting tour duty cycle on the plasma cutter?

It would be nice to know if the torch the computer finishes the pattern after the torch shuts off. Slow mo video may be required.

Not a chance, I run an Everlast powerplasma 50s

I’ll have to double check, I’m pretty sure mine only have single yellow lines one them…

Also looking at your design I cant tell whats supposed to be cut out completely and what is supposed to be just a line or if there is any like that. Are they all closed loops that should drop out?

I use sheetcam and I know that you can insert “tabs” is that even a possibility on Fusion? Could they be tabs?

Yup you can insert tabs but its something you couldn’t do by accident.

That’s a nice piece…I think I was looking at it backwards heh

You can insert tabs on fusion, however these are not tabs.

It is a nice looking piece when you finish it.