I’m sure this is something simple that I have missed, but when I have a number of parts on a Fusion 360 sketch set to manufacture, the Crossfire will cut one piece and then stop and give this message:

### TORCH STARTED MOVING BEFORE CUTTING VOLTAGE WAS SENSED

Below are the possible causes for this issue:

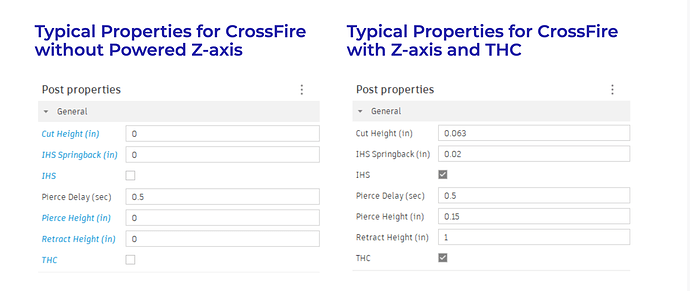

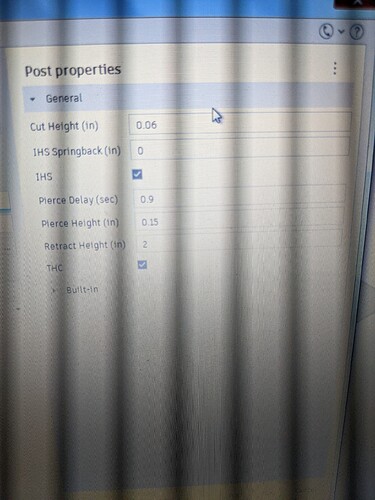

1. If your plasma cutter did not fire at all before the cut was stopped, the cause for this issue is that the pierce delay in your program is too short. As a result, the torch started moving before the plasma cutter arc turned on. We recommend going back to your CAM software and increasing your pierce delay to a minimum of 0.5 seconds when cutting on our machine. Additional delay will be needed for thicker material.

2. If your plasma cutter did fire before the cut was stopped, the cause for this issue is that the pierce delay in your program is too long. As a result, the torch burned out the pierce hole and extinguished before it had a chance to move. We recommend selecting ‘RETRY CUT’ and using the Pierce Delay Override to decrease your pierce delay.

3. Another cause for this issue is incorrect voltage wiring from your Plasma Cutter to the THC Port. Are you seeing a good Live Voltage (50-140V) reading in the THC CONTROL panel when the torch is on?If not, please make sure your THC is wired correctly and follow the THC Health Test Wizard in the THC Module or the LS-THC Troubleshooting Guide.

Then I select “retry cut”, then “load program”, then select “start” and it will cut the next piece. I have had to repeat this for every piece.

It can’t be number one or three, but I’m not sure it is even the second option, and if so where should I make this adjustment?

Am I selecting the body elements wrong in either Fusion or Crossfire 2D-profile?

MORE: If I turn off THC, it proceeds with the cut, so something is set wrong here, but I’m not sure what to alter. I have excellent THC live voltage when the cut it happening and THC is turned on, and it seems to work fine if I am just cutting one element. The THC is running all the default settings, and it passes the test mode just fine. Note I am not using lead-in or lead-out…is this messing something with THC up?