A good rule of thumb is a slot equal to or greater than the material thickness. You could go the entire bend allowance like @Erock89x example and you’re super safe…

The actual amount sits a little bit less than material thickness I’ll see if I can find the math I worked up for it at one time.

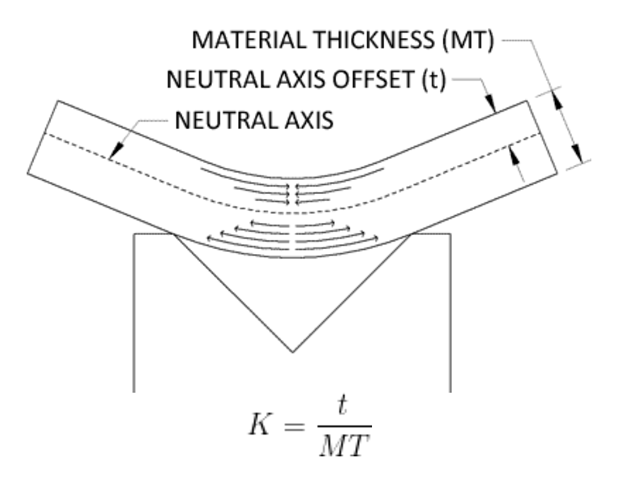

This picture illustrates where the problem comes in. At the inner Bend we’re dealing with compression everywhere from the neutral line to the inside radius (the neutral line offset) of the bend and we need to not have material there so we don’t crash.

Ultimately the best way to go about it is to do a few test bends with your particular equipment with different slot with and find The Sweet Spot for you.