another thing should I have got extra consumables when I purchesed this I did not

you always need consumables…lots of them…

punctuation would really help us understand what you are saying…

Are you using a desiccant filter before the inlet of your plasma torch?

yes change them every week

How long have you been running that set of consumables? Even in the best of circumstances, you will only get around 1500 pierces from a set. With less than ideal moisture removal, that could drop to 500 or less.

I was having some issues with my thc started looking around at the wiring and found the screw holding the wire tucked in by the z axis travel nut was loose. Tightened it up and all is good again.

2 weeks about 30 pices 24x48

I will check that out robert3

thanks for all the help every one ,got my new consumables dialed in my piercing times and cut speeds , and all is working good.

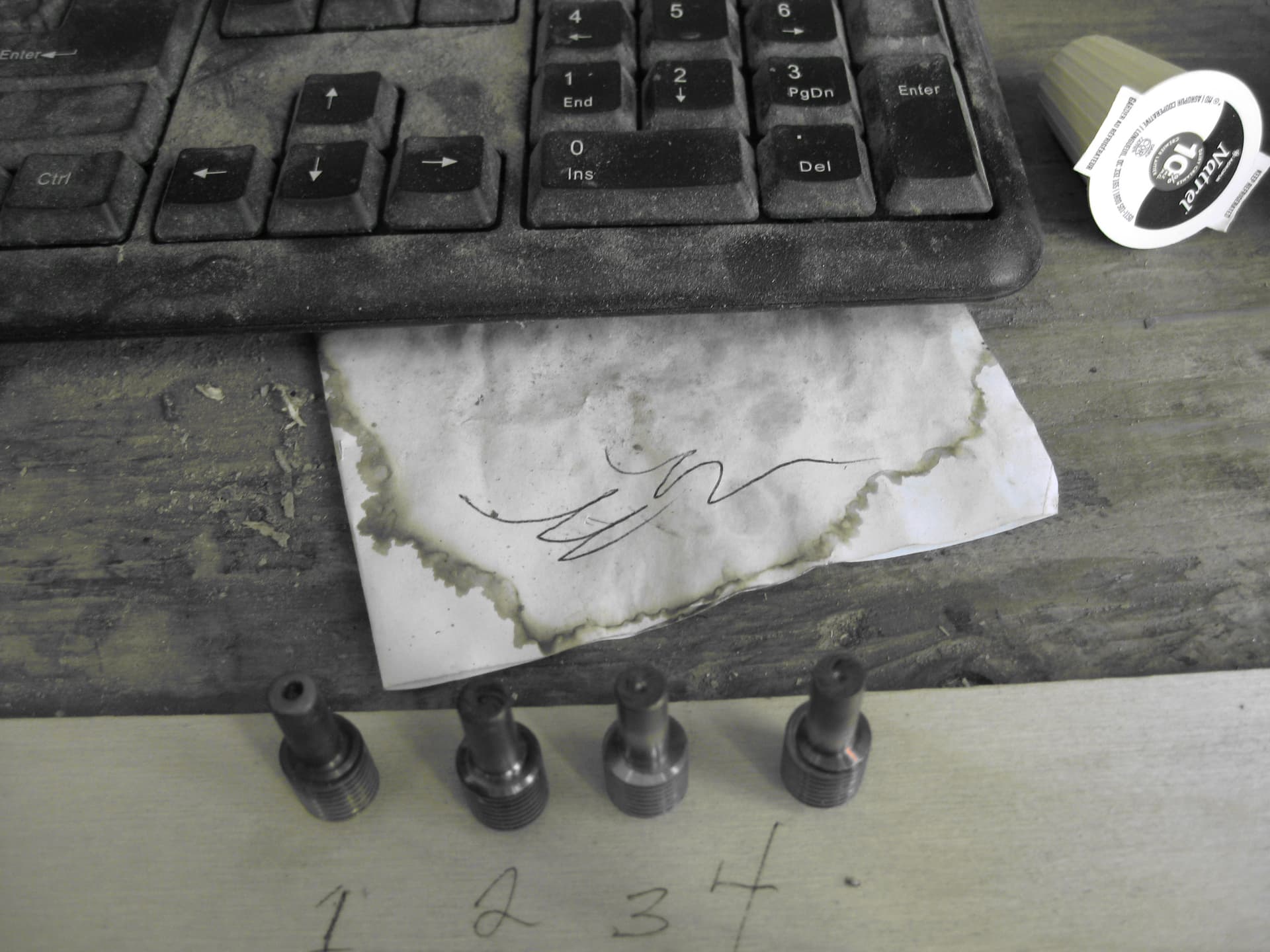

ok had no problems till today have been getting very bad cuts or no cuts after pierced I have attached new pictures of my last 4 tips

good clean air

1/16" material .3s pierce delay 120in speed about 200 pierecs on each

can any one tell me are these all bad please reply using the number if you have an opinion

You have to take better pictures, with the focus on the parts. From what I can see in those blurry pics, #1 is trash for sure. The rest are hard to tell without better pictures.

What cut height are you using?

What pierce height are you using?

(I did scan through the topic I didn’t see that information)

Where did you buy your consumables from?

They look oddly colored for the amount use you are describing. They look like they’re taking on a lot more heat than they’re supposed to.

And I know it’s been asked and answered a few times on this topic. I would scrutinize your air volume and quality unless these are some kind of knock-off consumables.

It is hard to tell from the pictures but one and four are totally wrecked and it seems like there’s a lot of conical shape around the nozzle of two and three.

You should not be going through quality consumables that quickly.

If your air is hitting your desiccant cell very hot then the air is going to be a great moisture sponge so some moisture will make its way through. Ideally your air temperature would be ambient temperature by the time it reaches your desiccant cell.

thank you for your input I have noticed one thing that has been bothering me the air is pushing the water from the water table up in to the torch head, it is real bad when it ends with an open cut the plasma cuter says around 90 lbs some times there is water every were evens plashing over the edge of the table on to the floor I was told the internal regulate is set optimal from the factory

my pirce rate is.3 but I noticed the picesed steel gets red hot and molten if I send to .5 or.6 fire control will not work

ok here are some numbers Kerf width .0591

pierce delay .3 s

pierce height .1181

plunge rate 5

Cut height .0591

I am cutting 1/16" cold rolled steel say 16g

Plasma cutter output flow air pressure should never be over 75psi. 120 to the plasma cutter is fine.

I hope that plunge rate is a typing error. That should be at least 50 not 5.

sheet cam has them all set at less than 5 if you are sure it should be 50 I will try that

should I open it up and turn it down

yes should be at least 50 but you can go higher. That’s basically the time it takes to go from pierce height to cut height and 5 is pretty slow.