Just realized this video was edited down to one minute, I must have posted the video under a different format which Instagram automatically edited out the most important part, which was the air options unit itself. Hoppefully this shows the whole video, 3 min long

Hey guys. Thought I would jump in here. I’m not one to rip companies apart, but I do want to offer a word of caution. It seems they have worked in certain situations, and I’m glad for those people. I have used two air options dryers. I live in indiana and we have 100% RH during the summer in the mornings and it can stay as high as 80% during the day. The shop floors will sweat a lot sometimes. That being said one had everything from 5cfm running through it to 30+ cam running through it and we still had major water problems in our sanders. The other stayed on the lower end of the cfm range and still had issues. I would have water all the way to my plasma cutter. Yes they were sized appropriately and yes the air pressure on the compressors was 150-175 psi dropping to 110-120 through the dryer. I even talked to the owner. For twice the amount you can get a refrigerated air dryer. That’s what we did finally. Not a drop of water since. Very happy now. Check out the polar air dryers. Made by Eaton compressor. That’s what we have and are very pleased. Also very reasonable compared to other brands. They are based out of Ohio. Both our air options dryers are on the shelf. Wish we would have just went to the refrigerant dryer first. It’s well worth it. Glad they work in certain situations. Just seem to have a sweet spot. Outside of that they don’t seem to work.

Yeah, I got all my set up from them, a 10hp compressor, air dryer, and 3/4" Max air line. Call Megan South. She is the best, and she gave me good prices that I could not pass! (No affiliation whatsoever)

This is what I have set up that I was referring to above. Air from compressor to the non-refrigerated dryer and then to the refrigerated dryer.

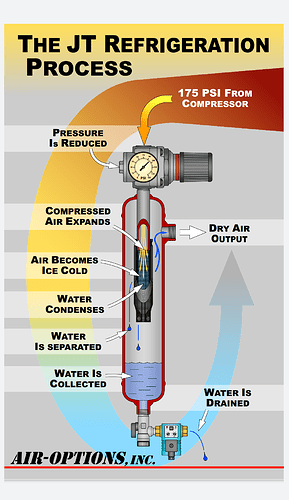

I believe the non-refrigerated dryer works most efficiently and giving best results while under a constant high flow rate being it’s only dehumidifying while air moves through it and creating the pressure drop within it.

At some point I may get a larger AC and then run a larger and more permanent line from tank to the first stage dryer. I think most what I’ll be doing will be smaller cuts anyway… just have to see how it all works I suppose.

I have an automatic drain purge below the non refrigerated dryer… I mention this because I just read above someone not having good luck with theirs and having water all down the line. If it’s not being drained (manually or automatically)… its certainly not going to work.

Correct me if I’m wrong… the way i understand this device works is that you are asked to provide 160-175psi from the compressor BUT you then adjust the output device pressure down to 100psi (preferred). So as long as your compressor can provide a consistent 100psi you should be good right?

Some background… I’m using a Eastwood qst-30/60 and the cut in @ 115psi and cut off @ 145…

Seems like my compressor will stay within the limits…

And my compressor is not your typical single stage (which is why i bought it  ).

).

Anyways… just my 2cents… look forward to your collective wisdom.

Your compressor has to output 160 to 175 CFM.

I read through the directions of that unit and it pretty specifically states that single stage compressors are not adequate.

100psi is the output after the dryer.

They likely based its CFM drying capacity on an input pressure of 175 and an output pressure of 100.

Anything less than this 75 lb of pressure drop you’ll have to start derating your units CFM drying capability.

I’ve been very interested in this Air dryer myself I have done quite a bit of reading about it.

Currently I have a more traditional setup which involves an after cooler, refrigerated air dryer and then a desiccant dryer.

Thanks for the wisdom… i get what you are saying…but… i guess what I’m hung up on is the valve used to adjust the pressure “output” is what feeds the device. right? or am i not seeing that correctly…?

That regulator is what creates pressure drop in the device, it’s part of the device.

That unit needs pressure drop to operate if you run 100 lb into it and you have 100 lb coming out of it it’s not going to do anything.

And to get your rated drying capacity you’ll have to have 175 in and 100out.

Anything less than this 75 lb of pressure drop is going to significantly reduce the capacity of this machine.

After all your drying is said and done you should always have a regulator before your plasma power supply.

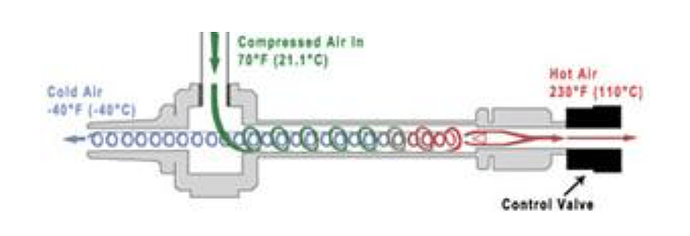

I should clarify a bit here it’s not just the pressure drop alone that causes the water to condense.

The pressure drop is creating a vortex and in this vortex it separates hot from cold this is the main cause of the condensation is that the cold part of the vortex condenses the moisture.

In the machining world there are some people who use vortex cooling nozzles which you Plumb compressed air into.

They’ve basically entrapped one of these inside of a vessel.

I find it interesting in their marketing they do all they can to steer around the fact ( vortex cooling) that that’s what they’re doing probably so other people won’t copy them.

That’s good info! Thanks!

Just buy a refrigerated dryer. All this stuff is cool and very impressive, but your problem will be over.

$450 from Harbor freight. A small molecular dryer on back end and your done. That Air Option LLC

Drier is between $350 and $650. Something to think about.

At this point that’s how ill proceed. I liked the idea of a simple (tho not cheap) solution… ill go with the harbor freight option… seems to be a widely accepted product by the Langmuir systems group. I appreciate all the input! one of the many reasons I bought into this!!

I’m using my this same dryer with a portable Sanborn air compressor. It has two cylinders (not sure if that specifically means it’s 2-stage). I had to dial up the cut out pressure a bit on it but it’s still within the specifications of the tank. I believe it cuts out now at 150 or 160… i could check tonight for specifics. I believe I’m set up to send 75 or 80 psi out of my equipment room out to my plasma cutter. But I have been extremely impressed with the air quality! I also run it through a refrigerated dryer but only when I’m actually using my plasma cutter. But I’m really not sure I even needed the refrigerated dryer to be honest. As long as you keep that 45-50psi pressure drop or more across that dryer it works great!

My only word of awareness (providing you stay within the safety limits of the compressor of course) would be to acknowledge how much you plan to use your cutter and how long each project will take to burn. I don’t believe the cfm of my compressor is quite the same as the cfm consumption of the Razorweld plasma cutter I have… so if you have extremely long cutting process for projects you could perhaps exceed the ability to maintain adequate pressure drop across a non refrigerated dryer like this.

Another thing to consider is with a smaller compressor and long cutting process you could have issues where the compressor runs so much that the compressed air becomes quite warm. Even with the 45psi pressure drop you still won’t see the reduction in dew point that you would with cooler compressed air Temps. This is why you see after coolers being installed.

Just something to consider

great information for compressors