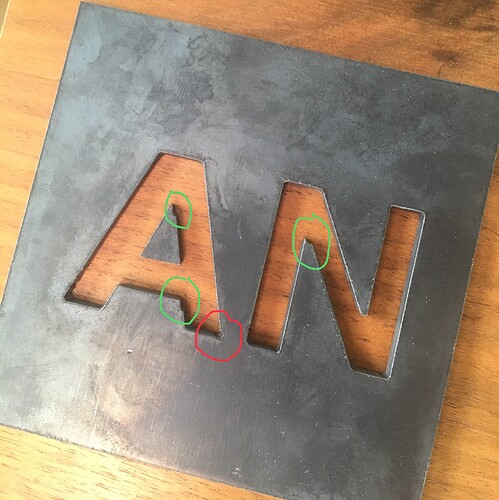

Hey there i just received the machine super happy new to plasma. Can any one point out why do i get this niche on my cut , green and red ones are a different characteristic? also cut is not 90 degree beveled edge

- I’m using razorcut 30I

- the material is 11 gauge mild steel

- watertable

- 60 psi

- 0.8mm nozzle

-CAM setting is same as Langmuir youtube video.

Double check your set screws on the ends of the lead screws.

It could be due to insufficient lead-in/lead-out values. The torch “sits” for a little bit establishing the arc (pierce time) and that causes a bigger cut into the steel vs a running arc following the line. A similar artifact can also be created when the torch turns off at the end before it moves to the next cut.

The lead-in/out values move the head away from the line and that notch is created in the waste vs the “good” piece you want.

1 Like

Thanks James. i dont think its pierce time because those green ones are not entery or exit point for touch. And they are all on same angle

Did you check the set screws as @Youngfab mentioned?

I’m not sure how that slips just in those discrete places though.

Thanks yep i’m going to check set screw and cut another one tonight thanks.

Hey everyone i just want to post for future users. those niches happened because of stepper motor coupler was loose and the shaft was skipping. tightened and all good now.

3 Likes