It certaintly looks like its only firing the pilot arc. have you reached out to Razorweld?

In your last pic is the 0.100 aluminium and 100 ipm sounds fast for 30 amps.

@langmuir-daniel

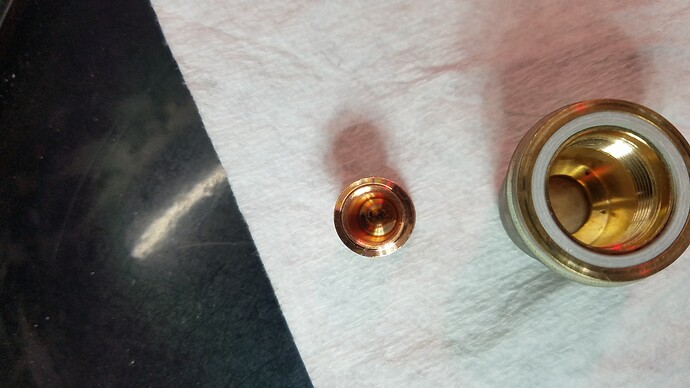

No I have not reached out to RazorWeld. I figured it was something stupid I was doing wrong… Still trying to figure out what is going on. It does this intermittently. I stopped Mach3 in the pic. Went back to zero. Left material in place. Put on another new tip, electrode, and swirl ring (getting expensive). Restarted Mach3. Back to zero. Restarted cycle from the beginning. This time it cut better, still some blowout. Cut all holes and slots decently. Cut all text except for a couple of the straight sides of some letters where it just etched. When it got to the parts continuous perimeter it cut it decent all the way around until it got about 3/4 of the way then etched the material for about 3" cut again for about another 6", etched again for about 3" then cut through to the end of the part. This part is 31"L x 6" W and is arched from one end to the other. It is not just happening with this part. Been having problems periodically for the past few weeks. What is weird is the first 20-30 things I cut turned out fairly well. Seems to be getting worse. I use to cut, finish, & ship out 10 of these a week by hand with a jigsaw, files, drill press, and sander, too much work so I bought this machine. This week I had 7 to ship one is going out and it’s Friday… Really need to get this figured out so I can pay for this thing. Thanks for your help in advance!!! Sorry for the novel…

How old is your material? Could be that you are not getting a good ground on the aluminum because of the oxide layer. Try sanding a small spot on the material and attach the ground clamp to that spot.

I am wondering about the cut speed if it is 0.100" with the VP30 at 100 IPM that sounds fast to me. I am thinking more like 50 IPM if you are 0.100" aluminium at 30 amps on a vipercut. but just guesstimating based on my Razorweld 45 experience and our limited cut spreadsheet.

Based on the excerpt below and assuming 0.100" and 30 amps I would try 50 IPM. The math isn’t perfect but I like the ball park. Also assuming clean dry air.

| Material | Thickness (in) | Gauge | Amps | Speed (ipm) | Model | Tip Size | Comments |

|---|---|---|---|---|---|---|---|

| Aluminum | 0.038 | 26 | 30 | 135 | RW45 | .9mm | on the money |

| Aluminum | 0.125 | 35 | 80 | RW45 | 1.0mm | Vitually no dross, Nice cut |

I also assume if you are not burning through your material that means more blow back and it would be much harder on your consumables. You are operating in a perpetual pierce.

Material is basically brand-new. It is touching the table everywhere I can see I also have a 25 pound cast iron weight on top of the material to hold it down. Air is dry, and you’re correct it is not cutting through in the place of it does not cut through there is a lot of dross on the top side telling me it’s blowing out.

Yeah I continue to have the same issue with mine with no better results. Been reading on other forums it’s the vipercut. You get what you pay for they say. New plasma is next on list. Thin stuff is fine but for 3/16 I use it’s terrible when it does cut.

@ItzEnsign Mine started out cutting fairly decent, this basically just started occurring. I realize the 30i isn’t ideal, but I shouldn’t be having issues like this. Can’t believe it is all in the torch…

It might not be. But you have to narrow it down. It’s either the Crossfire, the file or the cutter. There is the human factor but that’s going to show up in just one of those three.

The Crossfire in general with a good file & cutter can do it. Apparently you used to be able to do it as well.

That means it’s not likely to be the Crossfire. If a file you used to get to work doesn’t, then it’s not likely to be the file which would leave the cutter which does degrade over time and has its own set of troubleshooting factors (air, shims, consumables).

If an old file works then it’s likely the file(s) that are now failing for a potential number of issues which are user controlled.

Even though unlikely it is possible that the Crossfire electronics are the problem but we’ve seen here those failures tend to be full out - nothing works and either bad smoke is seen in the box or lights don’t light that should.

A methodical troubleshooting exercise is the only thing that’s gonna get you the answer though, tedious as it might be. One of those “gonna blow my Saturday figuring this out” scenarios.

Video of cut. Vipercut 30i @75 PSI with .060 shim @ 50 ipm using .100 aluminum And another brand new batch of consumables…

Here is the video of the above cut:

what is the torch delay it looks like it started moving as soon as the arch started? I wish you were local!

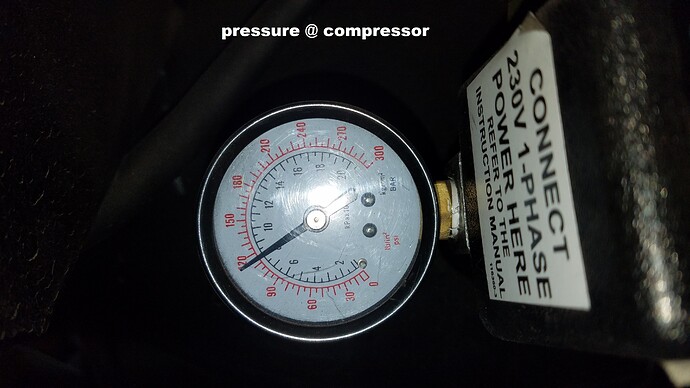

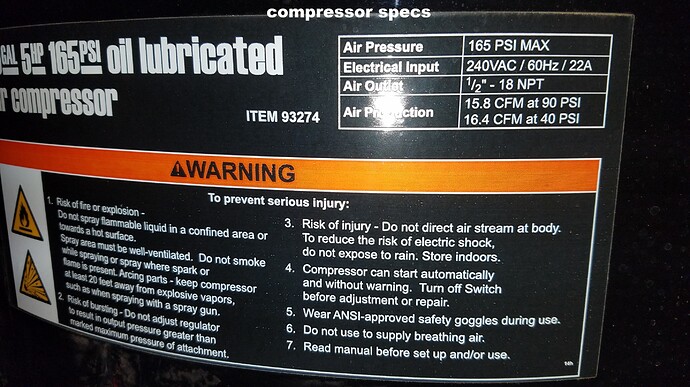

Another thing there is a regulator in you unit you line pressure from you compressor should be set to 90~ psi. Looks like 115+ in tank, 60 coming from the regulator and I am seeing 48 ish on your power unit looking at pics.

Your looking for 75 PSI flowing from the Razorweld manual I downloaded.

Beyond that the pierce delay must be long enough to get through the material and then some before the torch moves.

Alsdo for now move you work clamp (ground) directly to the work piece.

How close is this to your compressor? A desecant needs to be some distance away or it just becomes overcome. It appears you have moisture visivle in the first bowl.

There is a separator inside the machine but i plug one in just outside the machine as well. If you have another longer air hose put that inline.

I am thinking shotgun approach versus target attack.

I have a 30i and have had zero issues with it . Except ones i made. I have 75 psi at the cutter when cutting. Full line pressure up to the regulator on the cutter. I have noticed much below or above the 75 psi the cutting quallity suffers. I really hope you get yours figured out soon.