On the off chance I’m doing some incorrect here, thought I ask.

On assembly, attempting to secure the upper rail tube to the brackets securing to the table frame, I ran into a fairly large offset in the holes in the tube. It would appear that the holes on one side were punched 0.25" too close to the edge of the tube. I have a support ticket in already, but am I missing something?

Kinda disappointed, really looking forward to cutting something today. I don’t want to mill out either the bracket or tube and create a source for play down the road. Being impatient, I could fabricate a new bracket but don’t think I should have to.

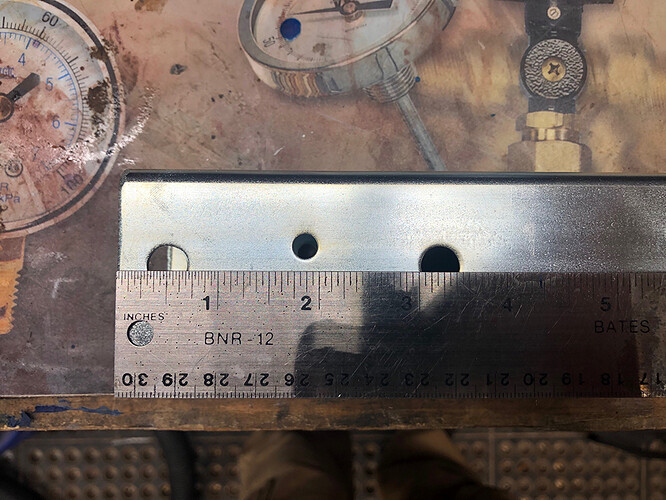

Picture of the left side of the tube

And of the right side of the tube

The left side tube is off to the left by 1/4"

The right side is correct and the left should mirror it. You’ll have to get in touch with Langmuir, Danielle usually answers pretty quickly for this stuff on the forum.

Honestly if it makes your weekend more enjoyable id mill it out for now. Langmuir will probably send you a new one anyway you don’t have much to lose.

Thanks for the confirmation!

“Honestly if it makes your weekend more enjoyable id mill it out for now. Langmuir will probably send you a new one anyway you don’t have much to lose.”

Yeah, I decided I was going to mill out the holes in the out of spec tube lying in bed last night. I’m dying to get started using the table!

As long as you only make it larger horizontally it shouldn’t effect anything anyway.

1 Like

We recommend doing this so you can get to cutting faster. We are going to send you new one though!

We built a custom hydraulic punch to put all those holes in the tube (it’s really a pretty cool piece of engineering, I should do a post about it sometime). The punch does 8 holes at one end in one hit. Then the tube is flipped around to do the other 8 holes with a pin locating one of the holes from the first end. This ensures that the spacing between the holes at each end are correct. Sometimes when the employees are flying through pallets of tubes they forgot to make sure that locating pin is inserted into the hole before punching the second side.

4 Likes

Awesome, thanks for the sending a new one so quickly! I went ahead and milled out the holes to fit the brackets and finished the assembly. I’ll swap tubes out when I get a chance.

Now to figure out how to hook up my older Miller 375

Great customer service, thanks!

2 Likes