I am using a Hypertherm xp45 with fine cut nozzle, it will not cut the S1 but cuts the S2 fine. I have made sure that the work piece is ground to the cutter. It does go through the motion and in Mach 3 the Torch On/Off F5 light flashes yellow as if its is firing but it does not, but then moves to the second outside cut and works fine.

Air pressure 85psi

45amps

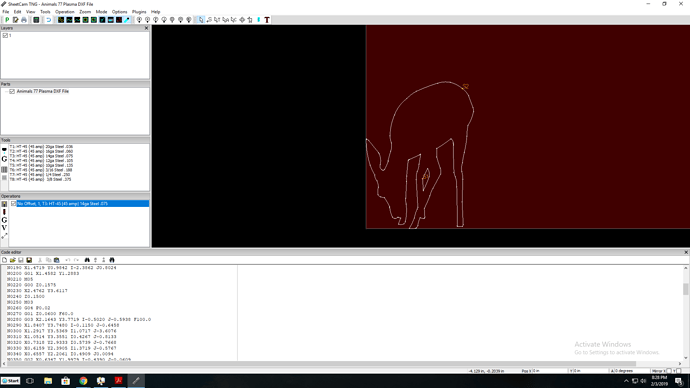

Here is the gcode that Sheetcam is producing

N0010 (Filename: Animals 77 Plasma DXF File2.tap)

N0020 (Post processor: Mach3 plasma.scpost)

N0030 (Date: 03/02/2019)

N0040 G20 (Units: Inches)

N0050 G53 G90 G91.1 G40

N0060 F1

N0070 S500

N0080 (Part: Animals 77 Plasma DXF File)

N0090 (Operation: No Offset, 1, T3: HT-45 {45 amp} 14ga Steel .075)

N0100 M06 T3 F100.0 (HT-45 {45 amp} 14ga Steel .075)

N0110 G00 Z0.1575

N0120 X1.4582 Y1.2883

N0130 Z0.1500

N0140 M03

N0150 G04 P0.02

N0160 G01 Z0.0600 F60.0

N0170 G02 X1.5835 Y1.5517 I3.7428 J-1.6191 F100.0

N0180 X1.6249 Y1.3439 I-0.2304 J-0.1539

N0190 X1.4719 Y0.9842 I-2.3862 J0.8024

N0200 G01 X1.4582 Y1.2883

N0210 M05

N0220 G00 Z0.1575

N0230 X2.4762 Y3.6117

N0240 Z0.1500

N0250 M03

N0260 G04 P0.02

N0270 G01 Z0.0600 F60.0

N0280 G03 X2.1643 Y3.7719 I-0.5020 J-0.5938 F100.0

N0290 X1.8407 Y3.7480 I-0.1150 J-0.6458

N0300 X1.2917 Y3.5369 I1.0717 J-3.6076

N0310 X1.0514 Y3.3551 I0.4267 J-0.8133

N0320 X0.7318 Y2.9333 I0.5739 J-0.7668

N0330 X0.6159 Y2.3905 I1.3719 J-0.5767

N0340 X0.6557 Y2.2061 I0.4909 J0.0094

N0350 G02 X0.6347 Y1.9979 I-0.4390 J-0.0609

N0360 G03 X0.5708 Y1.7603 I1.6779 J-0.5790

N0370 G01 X0.5684 Y1.7308

N0380 G02 X0.4723 Y1.5238 I-1.2171 J0.4397

N0390 X0.4015 Y1.5241 I-0.0352 J0.0349

N0400 X0.3654 Y1.6524 I0.0668 J0.0880

N0410 G03 X0.3377 Y1.9350 I-0.4592 J0.0976

N0420 G01 X0.3221 Y1.9612

N0430 G03 X0.0645 Y2.2785 I-11.7934 J-9.3087

N0440 X0.0135 Y2.3122 I-0.1276 J-0.1377

N0450 G01 X0.0041 Y2.3079

N0460 X0.0000 Y2.2929

N0470 G03 X0.1072 Y1.6332 I2.3147 J0.0375

N0480 X0.2221 Y1.3840 I1.4596 J0.5220

N0490 X0.2784 Y1.2403 I0.2166 J0.0020

N0500 G02 X0.3177 Y1.0739 I-0.3986 J-0.1819

N0510 G03 X0.3065 Y0.8782 I0.4140 J-0.1218

N0520 X0.3740 Y0.8243 I0.0863 J0.0388

N0530 X0.4734 Y0.8004 I0.1386 J0.3582

N0540 G02 X0.6036 Y0.5698 I-0.7980 J-0.6024

N0550 G01 X0.6093 Y0.5477

N0560 G03 X0.6758 Y0.3051 I0.7679 J0.0799

N0570 X0.8103 Y0.2963 I0.0704 J0.0442

N0580 G02 X0.8393 Y0.2944 I0.0132 J-0.0197

N0590 G01 X0.8885 Y0.2737

N0600 X0.8334 Y0.1216

N0610 G03 X0.9780 Y0.1308 I0.0624 J0.1609

N0620 X1.0134 Y0.1896 I-0.0591 J0.0756

N0630 X1.0345 Y0.6345 I-1.5253 J0.2953

N0640 G02 X1.0201 Y0.7857 I0.3721 J0.1118

N0650 G01 X1.0438 Y1.2155

N0660 G02 X1.0444 Y1.3631 I0.5272 J0.0715

N0670 G03 X1.0832 Y1.7602 I-17.8153 J1.9397

N0680 G01 X1.0972 Y1.7721

N0690 X1.1163 Y1.7843

N0700 G02 X1.3713 Y1.9000 I2.9364 J-6.1327

N0710 G03 X1.4013 Y1.9242 I-0.0648 J0.1110

N0720 G01 X1.4024 Y1.9137

N0730 G02 X1.3625 Y1.6656 I-2.7710 J0.3182

N0740 X1.3171 Y1.4759 I-0.4554 J0.0087

N0750 G03 X1.2921 Y1.2684 I0.4755 J-0.1624

N0760 X1.3326 Y0.5510 I43.8187 J2.1136

N0770 G01 X1.3134 Y0.5079

N0780 G03 X1.2430 Y0.2750 I0.8950 J-0.3978

N0790 G02 X1.1110 Y0.0105 I-1.6124 J0.6395

N0800 G03 X1.2855 Y0.0214 I0.0724 J0.2439

N0810 X1.3315 Y0.0863 I-0.0554 J0.0879

N0820 G02 X1.3891 Y0.2881 I0.8501 J-0.1335

N0830 G03 X1.4938 Y0.2674 I0.0862 J0.1604

N0840 X1.5146 Y0.2995 I-0.0121 J0.0306

N0850 G02 X1.5010 Y0.5268 I1.5161 J0.2047

N0860 G03 X1.6441 Y0.8522 I-2.8958 J1.4669

N0870 G02 X1.7225 Y1.0459 I0.6136 J-0.1357

N0880 G03 X1.9138 Y1.4012 I-8.5843 J4.8510

N0890 X1.9094 Y1.5579 I-0.2004 J0.0727

N0900 G02 X1.8193 Y1.8505 I3.2515 J1.1608

N0910 G01 X1.8194 Y2.0661

N0920 G03 X2.1768 Y2.3129 I-1.8978 J3.1306

N0930 G01 X2.1942 Y2.3099

N0940 G02 X2.2454 Y2.2057 I-0.0828 J-0.1054

N0950 G01 X2.2481 Y2.1807

N0960 X2.2497 Y2.1543

N0970 G03 X2.2626 Y1.4530 I11.7080 J-0.1363

N0980 X2.2974 Y1.3360 I0.4284 J0.0637

N0990 G02 X2.3334 Y1.0836 I-0.5849 J-0.2122

N1000 X2.3471 Y0.0737 I-34.2531 J-0.9709

N1010 G03 X2.3571 Y0.0637 I0.0063 J-0.0037

N1020 X2.4782 Y0.0671 I0.0551 J0.1927

N1030 X2.4998 Y0.1064 I-0.0231 J0.0383

N1040 G01 X2.4722 Y0.6917

N1050 G03 X2.4911 Y1.2753 I-35.7004 J1.4501

N1060 X2.4639 Y1.4777 I-0.9099 J-0.0193

N1070 G02 X2.4799 Y1.7025 I0.4905 J0.0780

N1080 X2.5277 Y1.9647 I1.8250 J-0.1969

N1090 G03 X2.5969 Y2.3862 I-2.9818 J0.7060

N1100 G02 X2.6252 Y2.6637 I1.0760 J0.0306

N1110 G03 X2.7642 Y3.0116 I-0.8586 J0.5448

N1120 X2.7499 Y3.1216 I-0.2532 J0.0230

N1130 G01 X2.6365 Y3.4257

N1140 G03 X2.4762 Y3.6117 I-0.4316 J-0.2099

N1150 M05

N1160 G00 Z0.1575

N1170 M05 M30