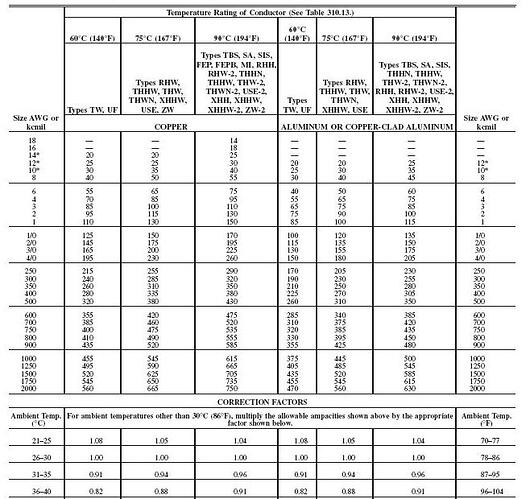

You are correct for solid copper romex, stranded THHN 10ga is good to 40A. Here’s the full NEC chart.

I believe that that chart is talking only about the wire itself in those specific conditions.

If I was putting in a 4 ton heat pump (40 amp) and I ran number 10 wire to power it here in Canada I would be forced to change it.

Here we look at it as a circuit as a whole and not its individual components.

And for sure it would work but it would not pass code and if my house burned down because of it my insurance company wouldn’t pay me out.

It’s all good,different countries different ways of doing things.

The Ampacity rating is related to heating of the wire due to its load and the load of surrounding wires. @BillA referenced THHN in conduit, which, according to the table has 40A ampacity. The asterisk refers to making sure there are no more than three identical conductors packed into the same conduit carrying the same load. Since it’s a single phase load, only 2 of the three conductors are carrying the load and therefore meets the spec. IF, on the other hand, OP used 3 conductor cable, that would not have sufficient ampacity for 40A load because the wires are bundled tighter than what you would get with individual wires in a conduit QED. ![]()

I am running solid 10g cooper wire that’s 28ft long. to twin 30amp breakers, i need to toss and amp clamp on it.

now as soon as I locate 6G wire. I am going to run that as I think I will be upgrading from the razor weld. I spent all day watching it stop cutting and resetting the breaker ![]() . That’s not going to be good for the machine. just cutting a test cut which is not cutting long runs.

. That’s not going to be good for the machine. just cutting a test cut which is not cutting long runs.

6061 - Aluminum 1/4" slowest cut is 15ipm /@45amp/.125 torch height, .5 pierce delay, and the cuts are not so bueno…hmm, back to the drawing board…(images to follow i know, i know, hehe)

Did some more research, my info was out of date (2002 edition) the 2008 edition states 30A for 10ga across the board in most circumstances. I’m a little out of practice on the AC side of things, been installing high amperage DC 100-200A constant load 1000A capacity telecom infrastructure stuff for the last 25 years.

There is an exemption for welding equipment to use the next size up breaker:

630.12 Overcurrent Protection

Overcurrent protection for arc welders shall be as provided in 630.12(A) and (B). Where the values as determined by this section do not correspond to the standard ampere ratings provided in 240.6 or where the rating or setting specified results in unnecessary opening of the overcurrent device, the next higher standard rating or setting shall be permitted.

Unrelated but trying to figure out how to do something. the goal of this beast is to cut signs, but I can’t wrap my head around all the parts needing to touch so that you don’t just have pieces when your done.

Can someone recommend a tutorial for me where I can see how? I have YouTube the heck out of inkscape and there’s lots out there, but i’ve got picture of a sun\moon that wife wants and it looks like it all connects till it cuts then its a waste of metal…grrrr.

bangin head on table…

Start a new thread in another category. This isn’t the topic to ask this question.

Copy, meant to send a PM to a member.

Cheers!