Hello, I am having issues with my plasma cutter. I purchased it through Langmuir last week when I purchased my CNC table. I got everything hooked up yesterday and make my first cuts. I purchased a sheet of 16 gauge steel and used the plasma cutter to cut it to 2x2 pieces. I then messed with the table and cut out a couple designs. Today I again tried my hand at CAD and cut out a couple other things. Everything was working as it should have. Hours later I needed to cut a piece of steel for something I was working on. I removed the torch handle from the plasma table and hit the trigger but had nothing. I tried multiple times, and once in a while it would fire, but not consistently. I changed the nozzle, swirl ring and electrode but it would still only fire intermittently. The electrode that was in it from the factory was so tight I feared snapping it off before it came out. It did mess up the threads a little and I had to run a tap in it to clean the threads. I did notice that even when the electrode is screwed in all the way, the swirl ring does not seal tightly when I hold the nozzle against it. I am not sure if this is supposed to be a sealed fit or not. Also, if I loosen the electrode slightly, about a quarter turn, the machine will fire consistently over metal, but extinguishes at the end of a cut, when the water from the table starts splashing. I tried making a few cuts this way but can tell something is wrong. Even when proper torch height is set, it does not have a uniform flame, cuts leaving slag, cuts are beveled and the nozzle orifice is elongated and about twice the original size after only 2 minutes of use. I have been reading about a possible burnt wire in the torch handle, but upon inspection it looks clean and dry inside the handle. Could you please advice me on what might be wrong with this machine? I have emailed razorweld and am awaiting a response from them. Thanks

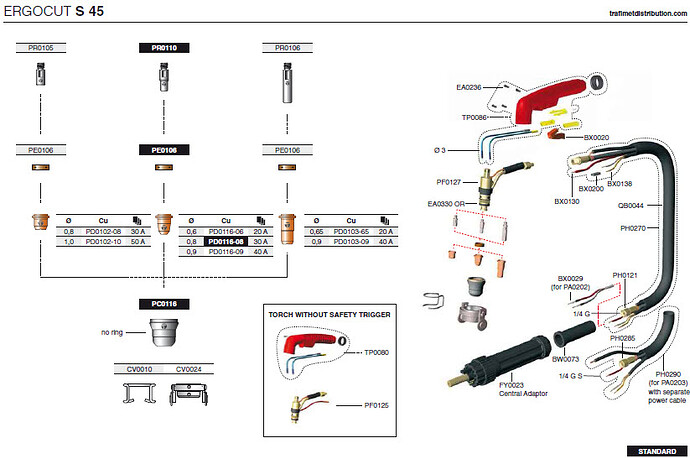

The original tip is a .8 mm tip which is only good to 30 amps, no greater. You need to buy the .9 mm tips to use the 40A setting. I figured this out after some trial and error. There are a ton of posts about it in the forum. You will also need to invest in getting the 1 mm tip and electrodes if you want to use the full 45 amps, but these are drag tips so you will have to compensate on torch height a bit.

I have read about the .8mm tip. I am only cutting 1/16” metal. No where near the need for more than 30 amps. I ordered a pack of electrodes and consumables at the same time I ordered the table. They are all .8mm also

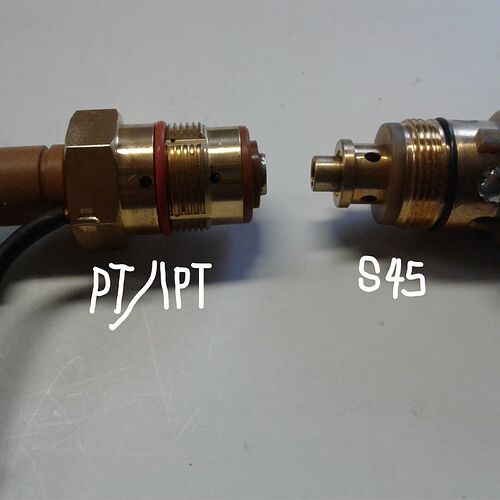

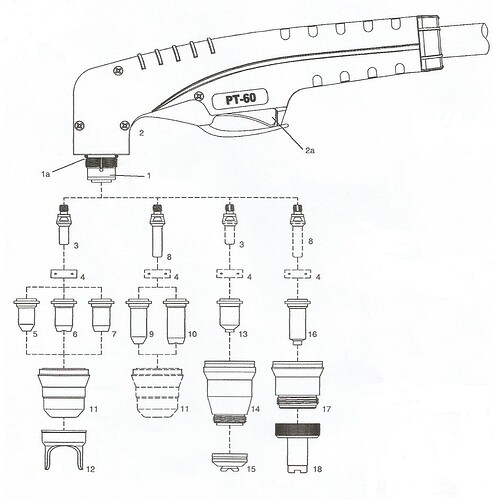

Its under warranty so they should take care of it. I am guessing your torch plunger is sticking from getting some dirt or blowback in it. I also think you will need a new torch head also to fix this problem. The torch pictured above (Trafimet S45) is not the torch you have you should have a Tecmo torch and it uses different consumables.

That makes sense. I can hear the plunger thunking. I didn’t notice this before. Anyway to take the plunger apart to check it out?

No, only replace the torch head.

So I came to the garage for another try at diagnosing this machine. I checked the air dryer and filter, and both are good. I decided to open the new packs of electrodes and nozzles that I ordered with the crossfire table. After install, I tried the torch out and it seems to be cutting fine again. Only difference is that sometimes it makes a whistling noise while cutting. I verified that the swirl ring blows clockwise if looking at it from the torch side, not the tip. Any guesses? Maybe the consumables that came with the plasma cutter are different than the ones bought separately from razor weld? Also, are these electrodes the same 30 amp ones that came with it or are they 40 amp?