Hi all, I recently upgraded to the Hypertherm 45XP from Vipercut 30(dead) and trying to get this dialed in. So shop setup is 60gallon air compressor with aftercooler and airfilter/separator befor the tank. Then routed to a new coalescing filter & desicant dryer in front of the cutter. I made approx 15 2" test cuts using low speed 14GA settings before this project with fine cut consumables. As you can see the first one is ok and the second is trashed(along with conaumables). Didn’t last 6 minutes on mach3 before it gave out. Any sugestions are appreciated.

What is your amperage, and ipm set at? Is your ground connected directly to your work piece?

I had it at 45amps and 150 IPM. I’m going cut both those in half today and do some test cuts and see if there is any difference in life and quality since I’m on running on 14 GA.

Pictures of the nozzle that show the exit orifice, closeup and in focus will help me help you troubleshoot. An addition to your installation that will help as well, install a pressure gauge tee’d directly to the plasma inlet fitting, after your filters. This gauge (if mounted as suggested) will allow you to read dynamic and static inlet pressures.

A couple of other things:

- Are you using the FineCut consumables? Shield # 220948, Nozzle 220930, Electrode 220842, Swirl Ring 220857?

- What did you set the torch to work distance at? Did you pierce and cut with this same distance?

- Is cut air pressure in “Auto” mode?

- What is inlet air pressure (measured at a gauge plumbed directly to the inlet fitting) with no air flowing at torch. What is pressure at same location with air flowing at the torch?

My suspicion is that the inlet pressure may be dropping when air is flowing…due to the number of moisture traps and filters, note that the size of the compressor has no effect on the dynamic (flowing) pressure at the inlet, however the restrictions created by filters, hose sizes, number of fittings, etc. does have an effect. Again, meaningless if this is not measured right at the inlet after any and all filters. I will tell you more after I see pics of the consumables (nozzle and electrode). You should get 1000 to 2000 cut cycles on a nozzle and electrode when everything is done correctly. Jim Colt

@jimcolt I’m going to watch this thread for info but a related question… what does Hypertherm suggest for moisture separation for this level of plasma cutting? Do dryer climates have less to worry about?

Not trying to hijack, but I’m curious about what consumables people are using successfully with the Hypertherm 45xp - I’ve had decent cuts at 45amps and 225ipm on 14ga steel, but I’d love to move slower at lower amperage for longer life…

Thanks!

-Ben

In dry desert climates there is little or no moisture content in air, so no additional moisture removal techniques are needed. I live in New Hampshire where there is low humidity for most winter months and high humidity for a few weeks in the summer. During high humidity I run my compressed air through a refrigerated dryer with an auto drain. During lower humidity I rely solely on the Hypertherm Powermax systems onboard coalescing filter with auto drain. How do I know when I need the refrigerated dryer? When I see water droplets inside the clear onboard filter bowl, or whe n I see a puddle underneath the drain line for the auto drain. Small amounts of moisture (contrary to p[opular belief created by those that sell filters and separators!) do not affect the Hypertherm Powermax systems like it does other plasma torch brands. I actually see more issues with air inlet pressure starvation that is caused by too many filters, traps, separators than actual short life created by a few drops of water. Now if you see oily residue inside the filter bowl…that will shorten consumable life rather quickly! Always mount a pressure gauge Tee’d directly to the plasma cutter inlet fitting as well, this is the only way to know the inlet air pressure to your plasma cutter in both static pressure and dynamic (air flowing at the torch) phases of operation. Jim Colt

For slower speeds look in your manual for the FineCut Low Speed cut charts. These charts keep the speed down below 150 ipm for machines that may not be stable at higher cut speeds required on thin materials. Jim Colt

Thank you for the replies, I just switched the shield to 948 from 931, 930 nozzle, 842 electrode, and 947 for swirl ring, not the 857.

.06 shim from table.

I assumed it is in auto as i haven’t touched it with. It was at 102 static and 90 dynamic. I did bump it up to 110 static and 98 dynamic reading with a guage at the machine.

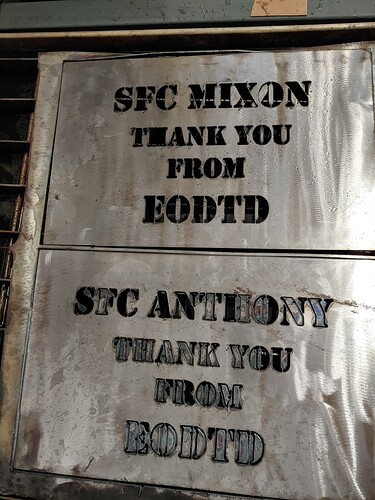

Did some new test cuts at 30amps with 150/175 delays. You can see the heat affected zone is fairly small and I think it was running too hot before killing the consumables.The one I liked most is left side at 85IPM

I have a different project I’ll give a shot at with these setting and see how the tip looks then.Got the project cut last night and was doing great now after lowering amps/speed and raising air pressure up

Nozzle has close to 200 pierces on it

Thanks MatthewGardner47 - I used 85ipm at 30amps in 14ga steel, and the cuts look really nice!

-Ben

Is the 1000-2000 cut cycles normal on the Langmuir table with no THC. I have a harbor freight v2 40a 220v unit. I bought consumables from George’s Plasma after speaking to him on the phone for about 1/2 hr. He was super helpful. My first tip only got about 250 cycles before the tip went bad and the cut splattered but did not cut through. Using .8 tip 25a /65psi/60ipm. Compressor is 60 gal. 2stage 19cfm@90psi with 1/2 " hard line and approx. 20ft 3/8 hose with 3/8 fittings set at 120 psi and 1 moisture trap. I would love to be convinced to purchase a new hypertherm powermax 45 xp if 1) cuts will be better and 2) consumables will last longer. Need to justify the initial cost of the unit.

I’ve never used anything but my 45xp so I’m have no experience with the other machines but I know from alot of the posts I’ve seen on here that folks are having issues that I dont.

@dfreyfbn I have the same cutter with an 80gal 2 stage. I upgraded from a smaller Huskey compressor that couldn’t really keep up with longer cuts but that didn’t help consumable life. What really changed the game was a refrigerated drier. I had just picked up a pack of authentic Trafimet .08s at the same time that i added the Harbor Freight refrigerated air drier and I’m still on the first nozzle with no wear after about 30 projects with maybe 400-500 pierces total. These were all at 30amps. Remember to only run the .09s at 40 amps. 40amps melts my .08s even with the drier.