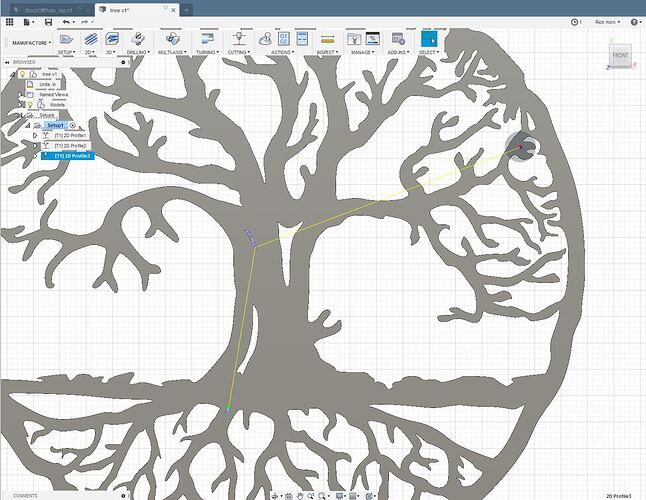

Even allowing for some breaks and comments in the G-code that tap file is larger than 39,300 lines I can see that taking some process time.

Thanks for the information. Never really considered it being an issue the error message I was getting is very vague so without more information for a rookie I wouldn’t ever figure it out on my own. Still confused why some of my existing tap files would not work.

Won’t work in Mach 3 to cut? Or you can’t regenerate the G-Code in Fusion for existing projects with defined toolpaths that used to work?

Yep we could be cross communicating and/or just off a touch haha.

Old files versus new files are likely somewhat a separate issue.

If the tap file ran in Mach 3 it should still run in Mach 3

Once a “.tap” has been created or “Post Processed” fusion is done with it. It can no longer do anything with it. You cannot simulate the path again unless you open an old project and you must use Actions-Generate (Ctrl-G) and that would recreate the simulated path. the you can Post Process again to recreate a .tap

With what James is showing that is the Setup and what will “show” your tool paths but the Post Process is always an output function after the visual tool paths

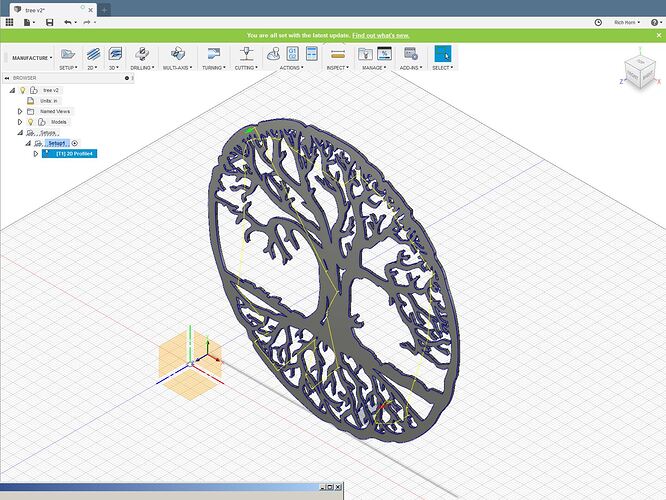

It is pretty cool artwork I can see in my mind some names and birthdays added creating a family tree

Interestingly, I was just about to go back to work (was !@#$ing off) and I downloaded the tree.f3D and that was your entire package with tool set up and all. After just reviewing some setting “No Changes” I post processed it with no issues sitting here at work.

Other than going with my own cut speeds I am going to have to cut this out.

Another interesting revelation at least for me. I never uses different speeds for me lead in and lead out but I can see why you may want to. Anyway again looking at the tap code there are 84 cut speed changes which going to the next step means 42 cuts. This is all meaningless but interesting as well. Did I mention I am on medication ![]()

Now I am going back to work.

I was about to leave work when I notice I had never closed fusion at that moment I also noticed four contours that were not cut out.

The little bugger on the bottom is only 0.050" wide. I had to reduce the kerf and change lead in and lead out to get it done.

The just for kicks I deleted the first three set ups and only used the set up for that last little hole. At that point it selected a single chain with no issue. It did take a long time to process. It repeatedly would show 0.0% like it was stuck and broken but it did it. At times it seemed broken but that is a lot of complex motion also with different lead in speed.

Those are the ones I generally ignore when I’m doing projects. It’s not like anyone else knows they were there or that they’re super-critical. Something that size just doesn’t cut well even without lead-in/out adjustments. It’s really just a pierce and move on. Part of using different CNC tools is choosing what to include & what to ignore - not all tools are capable of the precision that other tools are. (My laser kerf is 1/10th the thickness of the plasma kerf - lots of difference in what’s doable or looks good when finished.)

At this point I think he may have been just bogged down and needed to walk away and come back. It would have had issues due to linking constraints as I did just trying to do the four extra holes but if I said screw those holes I think his set up one may have done the trick. His set ups had different settings in the linking.

Now I am leaving work

Not able to regenerate a g code on most of my existing projects. I deleted all of my tools and started over. Most of my projects will now regenerate a g code. I also uninstalled fusion and deleted all related files and then re installed that also seemed to help

Richard and James thanks for looking at my issue and commenting I have learned a lot from this thread. Feel free to use my tree art. It’s awsome after its cut out

Agreed I had to unrealistically reduce his kerf and I knew I should move on (as this cut wont come out good) and really cut was just but a spec on his beautify peace. This was more an effort to just see if I could make it do it for better or worse. Even cutting some small screw holes in brackets I have found it better to just drill those but I do like having the CNC locate them for me ![]()

Really though this thread was good for me as well because I just do my own thing and it works for me. Sometimes I don’t notice features I could use. Sometimes searching for an answer to someone else issue helps me in ways I have yet to know. Other times it leaves me with other questions but that is good too

That’s actually a good use for small holes - just do a pierce point. Then use that as the pilot hole for a drill. A Unibit can help as well to size those holes. Just make sure you use a good bit - titanium for instance - as the edges of the holes can be work hardened and will be hard on standard metal drill bits.

Thanks for the offer. That’s very generous of you. I do like the design and may cut it and play with some Steel F/X patinas to see what it might look like.

I definitely need more free time ![]() Potential projects are mounting up.

Potential projects are mounting up.

What material did you cut that from?

14 guage cold rolled steel

I like using muriatic acid bath and then water and steal wool makes a nice rusty look or use old rusty steel as I have in the past

That would work well with the tree design - good idea.

I designed and cut this for my Daughters farm 1/4” rusty steel I had around the shop was gunna toss it out but decided to make this