I have had it with Fusion after the latest update none of my current cam files will produce a cut file and any new files with a lot of detail wont either and there is no support from Autodesk so is there another option of software out there I can use… If not I will have a crossfire for sale

Can you post a couple of the files you’re having trouble with? I did a fairly complicated one yesterday without any issues. I also re-ran a file I did a couple of months ago as I was testing my Crossfire after replacing a lead screw before I ran the new file.

Looks like I can get to it. I’ll give it a shot tonight after work.

ok thanks I would greatly appreciate it

James, I have been messing with it all day and tried making to separate cut files like top and bottom and it worked this makes no sense to me any ideas is it because I have a start up licence??

The license shouldn’t be an issue. The software is the same - just an accounting difference.

I’ll be heading home in a bit and will take a look.

ok thank you very much

Did you just change something? When I tried the link this morning on my phone I got to a page with a part displayed (looked like you had extruded it & everything) but now I get an “unauthorized to access this page” error on both machines.

I did not change anything I’ll resend it

here is the link I guess when I made two different cut paths the link a gave you was lost I had to create two cut paths to make it work not sure why https://a360.co/2Glorp9

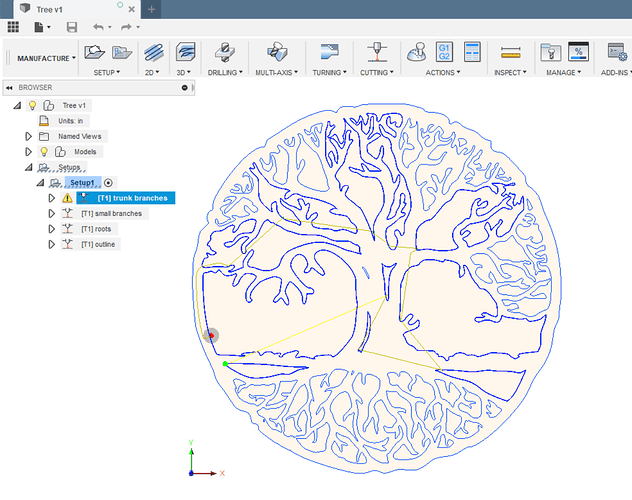

Seemed to work for me. I pulled it in as a DXF that I then created a setup with 4 toolpaths. Here’s what my Manufacture (CAM) view looks like:

BTW, I did it in 4 paths because when I did it all in 1 toolpath, it took a while for it to generate so I just did 4 separate groups of paths instead.

Here’s the G-Code - I had to add the .DXF to the end so it would upload here but if you rename it tree.tap it should load fine into Mach 3 and cut. There were a couple of bits that I didn’t include as they were pretty small and wouldn’t make it with a standard lead-in.

Tree.tap.dxf (1.3 MB)

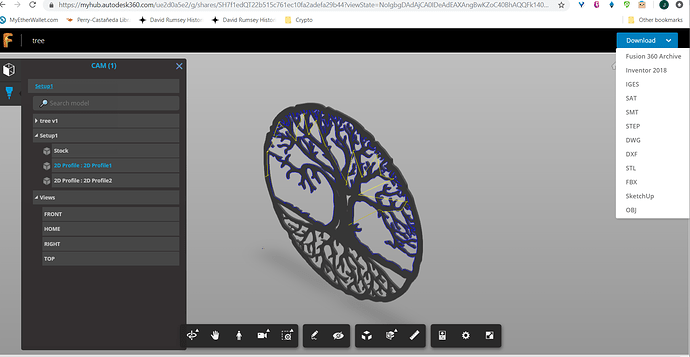

I didn’t bother extruding it - didn’t have an issue as a flat plate. I went to your link and downloaded the DXF per this picture:

Ok thanks I was able to do it in two tool paths not sure why it won’t do it in one tool path. I really am great full for your help Auto desk has not responded as of yet but I can work with this. Now to figure out why some of my existing tool paths won’t work now. Seems I am not the only person having issues with this as I have seen on the fusion forums. Again thank you for taking the time to help

Preston

It will but it takes a long time to generate. First it quickly showed the [0.0%] progress. Then the progress disappeared and then a few minutes later it changed back to the progress and took some time to get to the progress. It didn’t crash my machine but it wasn’t fast ![]()

I’m using a Windows 10 laptop with a Core i7 chip, 12gb RAM and an SSD. But it’s a little slower than I’d like because it’s got a standard laptop graphics card - not a high performing gaming one that would work much faster in the rendering operations.

I am using a brand new Lenovo think pad 16 gigs of ram 256 SSID and Core I5 also and I could never get a cut path just an error message I have not had an issue until fusion updated

I’ve got an i5 at work I can try it on. That may be part of it - the error you get may be a time out. That’s a pretty tricky design. Tons of nodes with all those squiggles.

Bet it’s nice when it cuts out. It’s a good looking design.

I cut one to night all was good until it caught the torch and moved the steel half way in wish I had a z axis took a few but was able to line it up close to finish the job Ill post a pic feel free to use it if you like

You can set a longer pause in the G-Code so that in between cut operations it waits long enough for you to reach in and pull out the tip-ups. I had that issue this weekend on a project I was doing. I have a couple of flat stock bars I can clamp the sheet to the table so I don’t move the plate. My Mach 3 pendant doesn’t have a pause so I have to be at the laptop to do that or just change the G-Code but then it wastes a bit more time while it waits. Not great for a commercial operation but okay for me - it’s just fun watching.

How do u set the pause that would be great to know how to do

I don’t know if there’s a place to put it in the pre-processor (I haven’t dug into modifying pre-processors to generate code) but you can edit the tap file with Notepad and change all M05 (torch off) to “M05 G04 X10” - put a carriage return between the M05 and the G04. This will follow every torch off (actually spindle off per G-Code standards) with a Dwell. In this case the pause will last for 10 seconds (X is seconds, P is milliseconds - I think better in seconds  ).

).