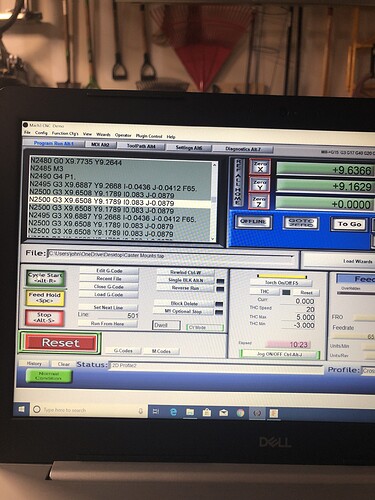

Every time I run a g-code it pauses. Just stops right in the middle like in this pic. I’ve re-programmed it in Fusion 360 and uploaded it several times and does the same thing in different spots of the program. Becoming very disappointed with my purchase. I literally bought everything brand new including the laptop to run on this table. I’ve had it for a few days and I’m considering shipping it back… road block after road block and no person to call for technical support… just this dang Forum

Did you buy the full license to Mach3? The standard demo is limited to 500 lines which is a surprisingly small and uncomplex part - my designs run into the thousands (& more) lines.

The screenshot shows the Demo version being used. If you bought the full version you need to enter the license key.

And it stopped on line 501.

Hi,

You have some strange things going on in your code. For example, you have three lines of code (N2500) that are duplicated three times. Additionally, line N2495 is duplicated in two different spots with lines in between.

How did you generate this code? The reason that it paused on that line is because the code is telling it to go to a point via an arc move that its already at.

Our team is very good about responding to people via our support email. They call customers when warranted (such as when issues can’t be resolved via email). We see that you submitted one support request earlier this week which was promptly answered.

The Mach 3 does show demo and 2500/5 is 500 so it will stop.

As Daniel mentioned the redundant lines that is weird. Just in that photo I see N2500 four times.

Hello, I’m having the same sort of issue. A) I purchased and entered the Mach3 license code when I got the crossfire B) i’m creating the G-Code from Fusion 360 C) if I look at the G-Code created in Fusion it’s fine D) when I try to cut it in Mach3 it freaks out and stops at 2500 along with renumbering the G-Code in the display window improperly E) it does this on many different G-Code files I’m trying to cut… Help!

Can you grab a screenshot of Mach3 and post it?

What’s going on with this now ? I’m having these issues and having a weird g code like the post above.

Notice that the three adjacent lines are identical. You probably need to simplify your design, it’s got too many short segments. Also, is you Mach3 paid for or is it a demo version? Demo version will only run so many lines.

ive got the licensed version of mach 3 yes… ive made a simple square to practice and get my settings right and it wont go completely through the code without freezing up.

Post your G-Code and indicate which line Mach 3 hangs up. If it’s just after the torch fires, it could be noise and there are plenty of discussions on how to diagnose/address that.

squard test.tap (424 Bytes)

it stops about line 12/ n60 on the gcode…

this is a screen shot from a video i sent to langmuir of the plasma freezing mid way. i cant post the video for some reason

That’s a microscopically small object! X min = 1.9744, Xmax = 2.058 and some of the motions seem pointless, like the line before the one where it stops, N55 G1 X2.03, N60 G1 X2.04. Why bother with N55?

How did you generate this file?

That’s weird , it’s supposed to be a 2”x2” square. I generated it in fusion 360.

Well, it isn’t 2x2. I think you have options:

- Go back to Fusion and find out why this output is not what you expected,

- Try to hand generate a 2x2 square cutout by manually generating a G-Code file.

Frankly, I’d try #2. You have a file that has the framework. Just modify and simplify the G-Code (it is really easy, probably MUCH easier than #1) to draw a 2" square.

How hard can it be? Assume you have the torch positioned at the lower left hand corner of the square. Let’s be bold and call that 0,0. So, position your torch to a spot in the metal and zero both axis.

Now, you want an ‘outside’ cut so you want to cut clockwise (don’t ask me why, just accept this). So, cutting clockwise (and forgetting the advantage of lead-in, etc.) turn on the torch. That’s an M3 code. Nothing fancy, just is.

To move clockwise from 0,0, you want to cut to 0, 2.100. Why 2.100? Well, you want a 2.00" finished square and you’re gonna have some metal lost due to ‘kerf’ and, to take a random number out of the air, we’re gonna say the kerf is 0.050" and you’re going to have two of them on each side of the square, hence, 2.100"

Continuing on to the next cut, Go or, in G-Code jargon, G1 X2.100. (the previous one was G1 Y2.100).

Next you have G1 Y0., then G1 X0 and your square is complete. Turn off the torch so you don’t melt your water table and you have your square.

Now, this might sound like it’s oversimplifying the problem and, yes, it is. But, that’s step one on the road to recovery. Learn to read the G-Code when you have problems, especially a 2x2 square. Most answers are simple ones.

Finally, this forum is the place to come when you’re stumped. We’ll do what we can to help you.

Now, back to Fusion. Once you understand what you need, play with fusion until it gives you what you want, or come back here to get help from the clowns… um, I mean, the Fusion Experts, who WILL help you. Honest. They are good guys, however, misguided.

Or a little more simply, check to see that your paths were “outside offset” cuts and not inside or no offset.

And check your kerf value. The 0.05" is a good place to start.

While you’re at it - do you have Mach3 and Fusion using the same units (")?

If you did specify the correct toolpath parameters and still have an issue, check your consumables. Make sure they’re not blown out.

Then try the handwritten G-Code. It is unlikely Fusion didn’t get it right - more likely you’ve got something else going on with user inputs or environmental factors worth focusing on.

Good suggestion if fusion even made the G-Code file, but there’s no header to indicate this. Doesn’t Fusion put a header comment at the top of the G-Code?