My torch will fire intermittently on jobs. I tried to cut 2 projects several times and it cuts less each time I run the program. I tried changing the consumables and it made it worse. It also cuts different parts of each file each time. The code shows the torch firing far more often than it actually does.

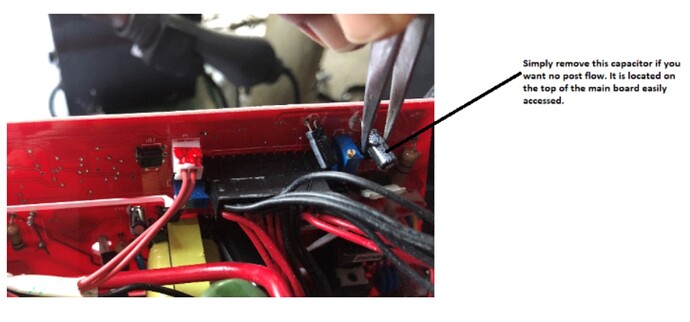

Hi there, this appears to be the postflow issue that has affected some of the Vipercut 30 machines. A few have sent their plasma cutters back to Razorweld for warranty repair, but the repair is actually pretty straightforward. Razorweld tech sent us the attached picture. Simply remove the capacitor shown and the postflow issue will go away.

I have a viper cut 30. And mine is acting similar. It will fire at the start of the program and run for a few seconds and then it stops. The program runs all the way through but the torch never fires again. Do you believe I have the same issue?

Thanks,

David Lipscomb

Does your torch complete the first cut fine, and then fail to fire on subsequent cuts? If so, then yes your issue is likely identical to OPs.

It does cut the first portion and then won’t fire again.

Do I need to do anything else or just pull it off the board?

According to Razorweld, you only need to remove the capacitor from the board.

I’m having a similar issue with a Razorweld Cut 45, however all the forum references have been to the 30. Have others with the 45 had the same problem?

I am still having this issue with my 45 as well, so I’m going to open it up and see if it has The same capicitor and if it does, I will be removing it as well

As odd as this may sound, I tried some Harbor Freight consumables and have had no issues since in my 45. Had to use both their tip (.9) and electrode but haven’t had a new failure to fire. Post flow still runs and cuts off when firing the next cut.

I saw those nozzles the other day at harbor freight, I am glad to hear they are working well.

I have to say that I am severely regretting my purchase at this point. I removed the circuit as directed and I got a few good cuts from it, and now I start again with it not firing for more than a second. I have had the machine for months and have not gotten an single good or consistent cut from it. So what do I need to do now to make this thing work? I am wasting all of my time fighting errors and shitty equipment. The vipercut 30 was the recommended cutter for it and that turns out to be junk that has to have part of the circuit board cut out and then still doesn’t cut. What do I do? between licensing and equipment I have a ton of money wrapped up in something that can’t be made to work.

https://www.youtube.com/watch?v=V4_oRtGEYgw&feature=youtu.be

@azguy We are sorry to hear your frustration. Have you reached out to Razorweld for the issues that you are experiencing? They should be your main point of contact for issues dealing with the plasma cutter and not the CrossFire machine. Anotherwords, if the plasma cutter is still not working as it should when cutting manually by hand and not on the machine then we can’t help and it will be something that you need to contact Razorweld about. They are good about getting machines fixed and up and running again. You can contact them directly by emailing sales@razorweld.com. If you are having touble reaching them then please contact us and we can escalate the issue.

Again we are sorry to hear about the issue that you are experiencing and we hope to get you up and cutting soon!

Hello, I am having same problem with my Razorweld 45. I have opened it up and cannot find any thing on the board that looks like the picture of the 30 amp machine. does any body have a picture of what we are to look for in the 45 to help with this issue?

The 45 board is different. Are you sure you have dry air, and have you tried new consumeables?

yes. but I am going to try other new consumables . I can put second dryer behind the T drop if i need to also. but the consumables i have had less than 15 min. on them.

I have had pretty good luck with making Parts off of my new machine but the last few days I have been fighting a bunch of problems with it will fire and cut one pass and then the next one it will not cut and then the next one it will cut and then the next one it will not cut I have to say I think this is a problem in my G-Code but I go and design the same part and start over and I go back to the machine and I have the same issue I have already took out the capacitor that is in the machine and it ran great after that now I’m fighting this other problem and do not know where to turn

That’s the same issue I was having as well. I could never fix it, so just ended up purchasing another plasma cutter brand.

well that’s nice to know I’m going to post a video here real quick of what mine’s doing if you would take a look at it tell me what you think because I’m getting ready to pull the trigger on a bigger machine and I’m buying a new cutter anyway I may just go ahead and speed up that process

Well it won’t let me post a video I was really wanting you to see it to see if that was the same issue that you had what cutter did you end up going with?