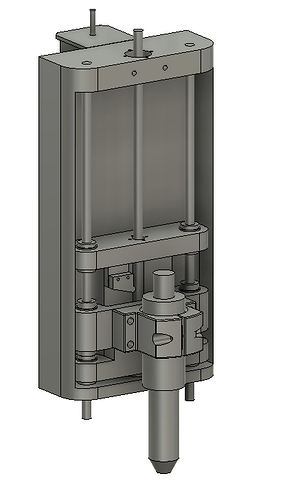

Here is the z axis that I’m working on.

Looks good, how you going to make it?

I plan to 3D print it.

Keep me in the loop i am very interested.

Looks awesome! I added a z axis to my table. Let me know if you have any questions not covered in my post.

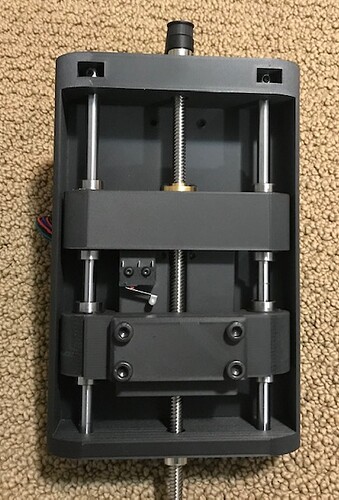

Here is the an update on the build. Mechanical assembly 95 % complete. Just need to trim mace rod, install spring and attach to Crossfire Table. I changed the design a little so you can use the original torch holder and a machine torch holder.

Just a little bit more refined then mine… Haha! Looks awesome! Can’t wait to see it working.

How long did it take to print the parts?

The large fixed unit was 2.5 days. Most of the others took less than 8 hours.

That should work very well. Very similar to the design we had on an early prototype except that the motor was on top directly driving the lead screw.

How tall is that print? You make it out of abs? Petg. I like this idea and it does not look heavy at all. Great job.

The main unit is 220mm long and all the parts are printed with Onyx.

How are you installing the z axis in the PLC box?

Is there a place in the break out board to instal a third control board?

I following this method to control the 3rd axis.

Very cool concept! Looking forward to seeing the finished results.

Two questions:

-

What kind of filament did you use to print those parts with? That matte finish is amazing.

-

Had you considered running the stepper for the z-axis remotely with a flexible drive shaft to reduce the overall weight of the z-axis assembly? I was one of the early adopters of the Zesty Nimble extruder and every time I see a stepper motor on a moving carriage I can’t help but think it would be better to be remotely mounted!

The filament is onyx which is nylon with chopped carbon fiber using a Mark Forge Printer. I have not considered running it remote. I designed it so the motor would counter balance the load on the bearings.

Thanks! I’ll have to give that stuff a try. Do you use a hardened nozzle or anything with it?

any chance we can get the STL files?

Not able to post STL here or on fireshare. Send me a private message and I can email them to you.

Any updates on this?

Now that I have a functioning 2x4, this is the next move…

I found a place to buy a completed floating head setup the issue is I lack the knowledge to do the electronics myself without someone to lead the way…

I just usually add “.DXF” to the filename extension so Discourse (the forum software) thinks it’s DXF and tell people to rename the file back to STL ![]()