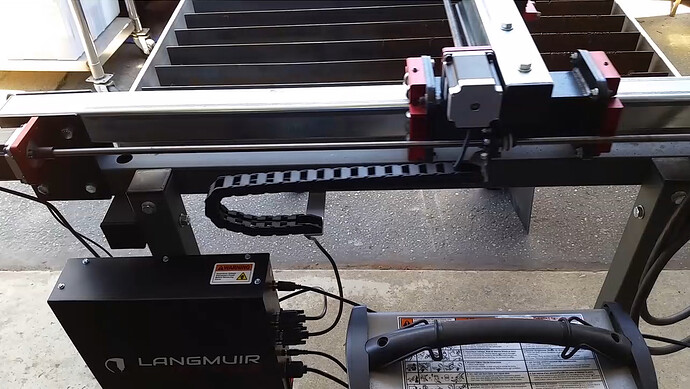

Got my system last week and decided to add a few things to it. I didn’t like the cords hanging around possibly getting damaged, having to stretch for outlets, I really wanted the plasma out of the way and easy to store and I also didn’t want water in the water table all the time or the hassle of filling it. I built a quick shelf for underneath. Here the Plasma can sit and I added a 19 gallon storage tub for the water tray fluid. Within the tub I ordered a $15 fountain pump from Amazon that feed to the top with /4" fittings. I need to add a 90 degree to the bottom on the outlet but it’s pretty close for now. For the pump I added a quick switch and a power strip with a 12ft cord. Also got a pack of velcro straps to keep things organized. Overall I’m pretty happy with it for a weekend project

Next thing I’d like to do is add a plug to the plasma for the trigger cord. Something like the one on the plasma controller box. I hate the cord sticking out of the bottom, it looks hokey to me. Anyone know what those plugs are called or know something with 2 connectors that may be able to be sealed with a dust cap? I check Mouser a bit but not too deep yet.

Nice!!! I really like the water storage/pump idea

That looks great, nice work. I’d like to throw out a few thoughts based on my experiences with having a 2x2 cnc plasma over the past 5 years

-

see if you can add storage under the table for your sheets of metal. Mine didn’t fit on my TM but one thing that drives me nuts is not having a place to put the new sheets or keep steel/stainless/aluminum separated and mostly for the pieces that are half cut and you are saving for another project.

-

cut out a little square cubby or pocket that you can bolt or weld to the bottom of the table or laptop stand. For your extra nozzles, tips, electrodes etc. Does the laptop arm swing? It’s nice to just keep everything together and fold things out of the way.

-

When you wrap an electrical cord that has current passing through it in a circle (remember the copper wire around the nail in school) you create inductance which can put more stress on the power source. I have seen this damage tig welders power boards before. A plasma power source is no difference. Even if you are stick welding and the cord has a few loops on the ground you will notice that metal shavings will start to stick to it. Don’t make your machine wear out faster by doing this.

All good callouts.

There is extra space on the shelf for more storage. I was going to add a small shoebox size container to hold some of the consumables and extra parts. They are ~$1 at Home depot and have a lid to keep things cleaner.

Storage for the extra steel is also a good callout. I’m working on a large scrap holder already for other fab leftovers. Still working on final design.

I didn’t think at all about the wrapping of the cords, you make a good point. Maybe I’ll look for a shorter power cord rather than wrapping it. I’d be interested to know from the Langmuir guys if they think this will also be an issue.

Wrapping up a 120 or 220V cord is not an issue since the cable carries the neutral in it, the inductance is cancelled in the alternating (AC) waveform. The DC output cable of any machine is a different story and when coiled around something ferrous it can cause induction or eddy current which can be damaging or harmful.

I purchased 5.5mm x 2.5mm sealed dc power female panel mounts (2) with waterproof covers, and (1) male 2m adapter cable, (1) male solder end. Waterproof and screws in securely.

Parts are Switchcraft:

JCAP

L712AS

761KS17

CA761KS07984

Steve,

If you don’t mind sharing, how did you put together the storage tray (purchased or angle iron and grate welded), and is it just mounted with bolts or screws to the legs?

Thanks in advance!

As long as there is some discussion going on about mods and add-on’s (albeit not for a while)… I’m wondering for those with the water table add on, how much ends up splashing out onto the electronics board mounted to the side of the table?? I was thinking this would be one of the first things to protect… Any thoughts or things you’ve already done to make sure this is not an issue??

Thanks for your thoughts…

Bill.

I was gonna say none but I went out to look. It is some but the electronics are in a box that shields them. There’s maybe 10% the residue that is on the gantry or the Y axis stanchion plates. Those seem to block the bulk of the water overspray.

Here’s the one I plan on using.

SZJELEN 13mm 2Pin Industrial Electronics Cable Connector Plug Socket,Outdoor Waterproof IP67,LED Light Power Connector https://www.amazon.com/dp/B07C4KQLPD/ref=cm_sw_r_cp_tai_DpKMCbJ143DCB

Here’s what I did to shield the control box.

Great idea ryt!

Thanks for sharing.

I like the water shield, I’ve seen some splash on the box so I’ll do something like that too!

My first mod was to take care of the dangling cable which was getting dragged over the enclosure and getting caught on stuff I stored under the table.

I found a way to use the stock cable and a cable guide (from Amazon) which worked out rather well. It was also the first ‘real’ bracket I cut on the new machine.